RFID Laundry Tags for Industrial Laundry

Customized RFID laundry tags for secure, automated tracking and efficient management in industrial laundries.

How RFID Laundry Tags Revolutionized Linen Management for a Swiss Hotel Group

In increasingly demanding industries such as hospitality, healthcare, and industrial laundry, efficient textile management is more than just a logistical requirement- it’s a competitive advantage. A Swiss hotel group recently redefined industry benchmarks by implementing RFID laundry tags across multiple European properties, resulting in unprecedented operational efficiency, cost savings, and increased guest satisfaction.

This real-life example shows how RFID laundry tags can revolutionize industrial laundry management, particularly in environments where thousands of pieces of linen are processed daily. Let’s explore how RFID works, why it’s become so popular, and what specific benefits have emerged from this large-scale deployment.

What Are RFID Laundry Tags?

RFID laundry tags (Radio Frequency Identification) are small, durable chips embedded into textiles, such as towels, bed sheets, and uniforms. These tags store a unique identifier and transmit data wirelessly to RFID readers placed at various checkpoints.

Unlike barcodes or manual records, RFID laundry tags offer the following advantages:

- Non-contact scanning

- Automated tracking and updates

- Resistant to industrial washing

For high-volume industries such as hotels, hospitals, and industrial laundries, using washable laundry tags can increase transparency, reliability, and real-time inventory visibility.

Real Case Study: Swiss Hotel Group Revolutionizes Linen Tracking

The Challenge

A well-known Swiss hotel group operating in several European countries was experiencing increasing inefficiencies in its linen and textile management system. Key issues included:

- Time-consuming manual inventory counting

- Loss and misplacement of linens

- Inaccurate inventory levels

- Time-consuming and laborious reconciliation

- Low accountability in third-party laundry services

Despite working with reputable industrial laundries, the group still frequently encountered inventory disputes, overstocking, and an insufficient supply of linens during critical periods, which directly affected guest satisfaction and operational processes.

The RFID Solution

The group uses embedded RFID laundry tags in all their linens, uniforms, towels, and other frequently used textiles. These washable, durable laundry tags were sewn or heat-sealed into fabric pieces and registered in a centralized database.

Each RFID tag held a unique identifier, linking it to metadata such as:

- Item type (e.g., king-size bedsheet, staff uniform)

- Size and brand

- Property or location of use

- Number of washes and current condition

- Date of purchase and expected lifespan

Over 2 million RFID laundry tags were deployed within months—an indication of the hotel’s confidence and a rapid return on investment (ROI).

How RFID Laundry Tags Work in the Laundry Process

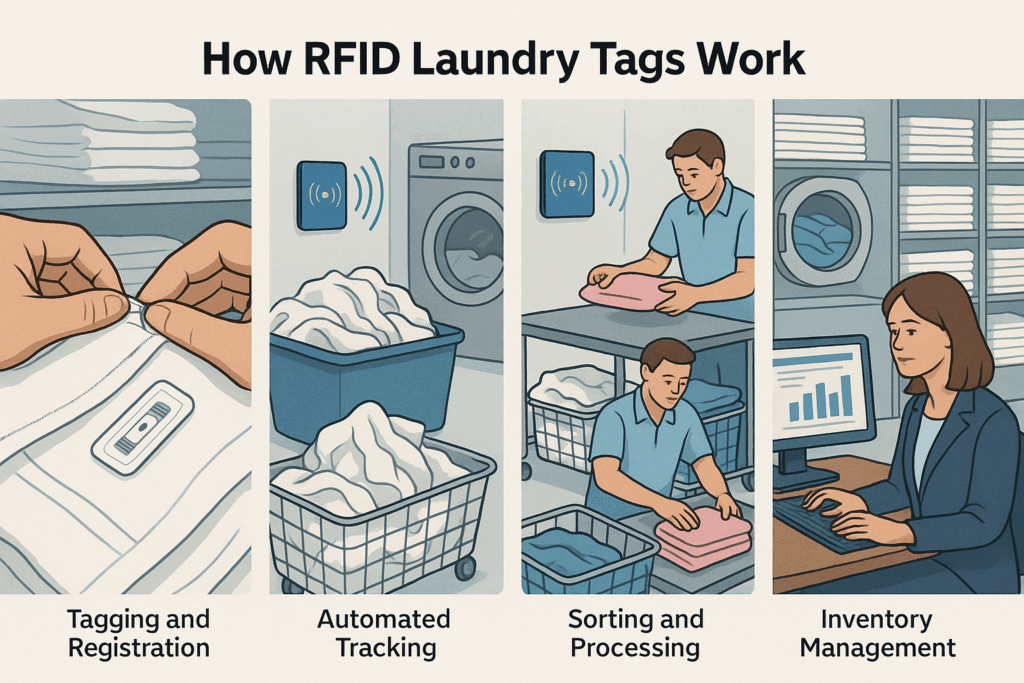

To fully understand the value, here’s a step-by-step breakdown of how RFID laundry tags optimize industrial laundry workflows:

1. Tagging and Registration

Every item—like a bed sheet, towel, or uniform—gets a washable laundry tag sewn in. Each tag has a unique code. This code is linked to a database that stores information about the item, including its type, owner, and the number of times it has been washed.

2. Automated Scanning

RFID readers are installed at laundry collection points, washing machines, dryers, folding stations, and dispatch zones. As tagged items pass through, they’re scanned without manual input, enabling automated data capture at each stage.

3. Sorting and Prioritization

RFID-enabled systems sort items by customer, linen type, or urgency. Uniforms from a spa are sorted separately from guest bedsheets, for example. This minimizes errors and significantly speeds up the process.

4. Inventory Management

Because every scan updates the central database, managers always know the exact number of clean and dirty linens. This prevents both overstocking (which wastes money) and running out (which makes guests unhappy).

5. Loss Prevention

Alerts are triggered when items go missing or are not returned after washing. This feature greatly reduces theft or misplacement, especially important when dealing with high-cost, high-turnover items.

6. Data Analytics and Reporting

All the data gets stored and can be analyzed later. Managers use this to check:

- How often are items washed?

- When things need replacing.

- Where the process can be made even more efficient.

Key Benefits Observed in the Swiss Hotel Case

70% Reduction in Counting Labor

By automating scanning and reconciliation, the hotel group reduced labor hours spent on manual counts by over 70%. Employees could now focus on more guest-facing responsibilities, boosting operational efficiency.

Improved Guest Satisfaction

With consistent linen availability and higher quality control, complaints about “missing” towels or stained sheets dropped significantly. RFID improved turnaround time and accountability across the board.

Inventory Accuracy Above 99%

Automated tracking provided real-time data, dramatically reducing discrepancies. Monthly reconciliation tasks were transformed into weekly reports, resulting in less than 1% variance.

Repeat Orders & Trust in RFID Solution

Impressed with results, the hotel group placed multiple repeat orders, eventually exceeding 3 million RFID laundry tags across their European operations. This strong vote of confidence shows how transformative RFID can be.

Why RFID Laundry Tags Are Better Than Barcodes or Manual Logs

| Feature | Manual Logs | Barcodes | RFID Laundry Tags |

|---|---|---|---|

| Hands-free scanning | ❌ | ❌ | ✅ |

| Multi-item reading | ❌ | ❌ | ✅ (read entire cart) |

| Survive washing cycles | ❌ | Limited durability | ✅ (washable laundry tags) |

| Accurate item-level tracking | ❌ | ✅ (if used properly) | ✅ (high precision) |

| Time efficiency | ❌ | Moderate | ✅ |

Final Thoughts: A New Standard for Industrial Laundry Efficiency

The Swiss hotel group set a new industry benchmark by using RFID laundry tags across all linen operations. The results were measurable and repeatable: lower labor costs, higher guest satisfaction, improved stock visibility, and increased scalability of efficiency.

As washable laundry tags become standard in modern textile management, businesses unwilling to adapt may face rising costs, inefficient processes, and weaker client satisfaction. RFID is no longer a futuristic concept—it’s a present-day competitive advantage.

If your business deals with thousands of textiles per month, consider this real-world success story as a clear signal: the future of laundry management is RFID.

Ready to upgrade your laundry operations?

Learn how RFID laundry tags can simplify your textile management and reduce costs- contact us today for a custom solution!

Industry-Wide Applications of RFID Laundry Tags

This technology isn’t just for hotels. Across healthcare, fitness, and industrial laundries, RFID laundry tags are solving long-standing problems:

Professional Industrial Laundries

Accurate client billing

Real-time updates on client-owned inventory

Lifecycle reports for wear and replacement planning

Luxury Spas and Resorts

Segmented inventory for spa robes, towels, and bedsheets

Higher quality assurance for guest amenities

Seamless vendor coordination and audits

Hospitals and Clinics

Infection control via sealed laundry tags for clothes

Batch tracking for surgical gowns

Better turnaround on emergency linen loads