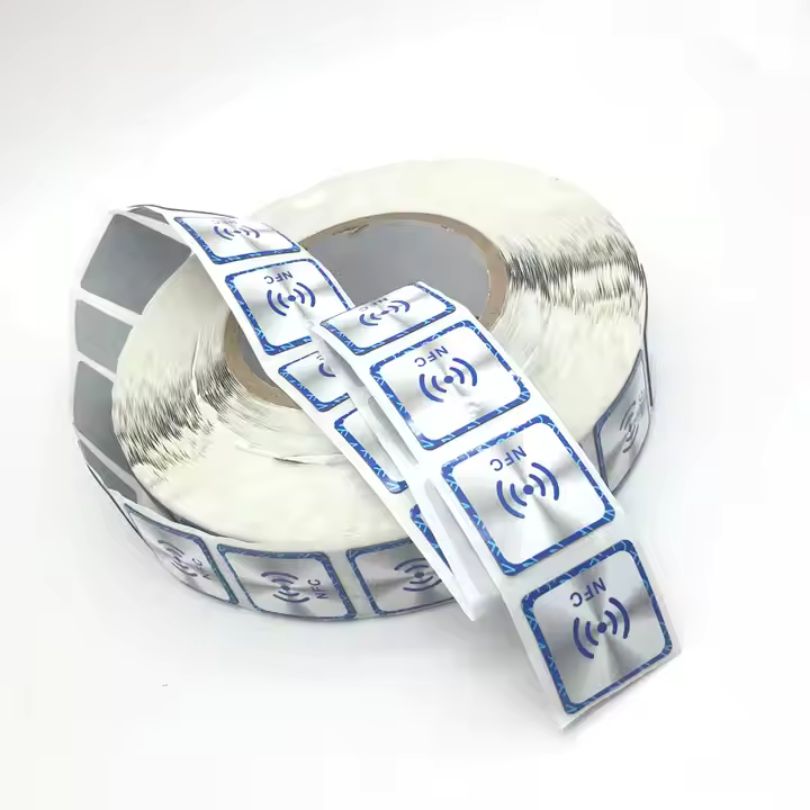

Customized Size Logo Anti-metal Printable NFC Sticker Tag

The Versatility of Customized Size Logo Anti-metal Printable NFC Sticker Tag

Near Field Communication (NFC) technology rapidly transforms various industries, from retail and logistics to healthcare and security. The humble yet powerful NFC sticker tag is at the heart of many innovative NFC applications. These small, adhesive labels embed NFC chips, allowing seamless data transfer and interaction with compatible devices, primarily smartphones. With the advent of customized size and logo anti-metal printable options, the potential of NFC sticker tags has expanded exponentially, offering tailored solutions for an even wider range of applications.

Unlocking Potential with Customized Anti-metal NFC Sticker Tag

Standard NFC tags struggle on metal surfaces, where interference disrupts communication. Anti-metal NFC sticker tags solve this with specialized shielding, enabling reliable performance even when directly affixed to metal. Custom size and shape options further enhance versatility for applications from discreet asset tracking to prominent product authentication.

The printable surface offers another key advantage. It allows businesses to incorporate branding, product information, and QR codes for enhanced visibility and interactive marketing. Imagine customers instantly accessing product details with a simple scan.

Customization also extends to the NFC chip itself. Choosing the right chip (like the common NTAG213 or more advanced options) ensures that the NFC sticker tag perfectly suits specific needs, whether they require basic functionality or robust security and data storage.

Technical Specifications and Applications of Anti-metal NFC Sticker Tag

These customized NFC sticker tags are designed for easy integration and reliable performance. Their robust construction ensures they can withstand harsh environmental conditions, making them suitable for both indoor and outdoor use. Durable materials like coated paper, PVC, PET, or epoxy protect the NFC chip from moisture, dust, and physical damage.

Here’s a table outlining the key technical specifications:

| Feature | Specification |

| Frequency | 13.56 MHz |

| Protocol | ISO14443A, ISO15693 |

| Chip Options | F08, NTAG213, MF1k, Customized |

| Material Options | Coated Paper, PVC, PET, Epoxy, Artpaper, Thermal paper |

| Size Options | 1818mm, Dia26/30mm, 3535mm, Customized |

| Reading Distance | 1-5 cm (Depends on environment and reader) |

| Special Features | Anti-metal, Waterproof/Weatherproof, Printable, MINI TAG |

| Customization Options | Logo printing, UID printing, Encoding, Barcode, QR code |

| Communication Interface | RFID, NFC |

| Typical Applications | Access Control, Cashless NFC Payment, Asset Tracking, Product Authentication |

The application possibilities for these customized anti-metal NFC sticker tags are vast:

Asset Tracking: Track tools, equipment, and inventory in manufacturing and logistics environments, even when attached to metallic surfaces.

Access Control: Secure access to buildings and restricted areas using NFC-enabled tags.

Product Authentication: Verify the authenticity of products, preventing counterfeiting and protecting brands.

Cashless Payment: Enable quick and easy contactless payments in retail and transportation settings.

Interactive Marketing: Engage customers with NFC-enabled marketing campaigns, providing product information, discounts, and personalized experiences.

Healthcare: Track medical equipment, monitor patient adherence to medication, and facilitate secure data sharing.

The Future of NFC Technology with Customized Tags

Customized size logo anti-metal printable NFC sticker tags are paving the way for a new era of NFC applications. Their ability to overcome the limitations of traditional NFC tags, combined with their customizable design and robust construction, makes them a versatile solution for a wide range of industries. As NFC technology evolves, these customized tags will play an increasingly important role in connecting the physical and digital worlds. Businesses that embrace this technology will be well-positioned to leverage the power of NFC for enhanced efficiency, improved customer engagement, and increased profitability.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.