RFID Inventory Tags for Warehouse

Customized RFID inventory tracking solutions for efficient, accurate, and real-time warehouse operations.

How RFID Inventory Tags Are Transforming Warehouse Management: Real Case Applications

Introduction: Why RFID Inventory Tags for Inventory Matter

In modern supply chain management, accuracy and speed are everything. Traditional barcode systems require manual scanning, which is time-consuming and prone to errors. This is where RFID inventory tags come in.

RFID (Radio Frequency Identification) technology allows businesses to track goods automatically and manage stock levels in real time. By using RFID inventory tags, companies can reduce labor costs, improve warehouse efficiency, and eliminate human mistakes.

Today, I’ll break down a real-world case of RFID inventory management based on actual warehouse and logistics operations. We’ll look at how RFID is used in various warehouse processes—from inbound to outbound, shelf shifting, and inspections. Throughout the article, you’ll see how RFID inventory tags support smarter, faster, and more secure warehouse operations.

How RFID Inventory Tags Work in a Warehouse

1. RFID Warehouse Inbound Management

Before goods enter the warehouse, an RFID inventory tag is attached to each item or pallet. This tag contains a unique ID, product information, batch number, and specifications.

When the goods arrive, RFID fixed readers installed at the warehouse gates automatically detect the tags. The system compares the scanned data to the warehouse management system (WMS). If everything matches, the items are accepted. If not, the system flags the error.

Key Benefits:

- Automatic identification of goods

- No need for manual barcode scanning

- Reduces inbound processing time by up to 90%

This process helps companies avoid mistakes like receiving the wrong quantity or incorrect products. It’s a core part of RFID inventory management.

2. Real-Time RFID Inventory Tracking and Stock Monitoring

One of the biggest challenges in an RFID warehouse is keeping track of stock levels. With RFID tags for inventory, warehouse managers can scan the entire warehouse in minutes using handheld or fixed RFID readers.

Instead of counting items one by one, the system reads all RFID inventory tags at once, even if they’re inside boxes or pallets.

Real Case Example:

A logistics company in Guangzhou implemented RFID handheld terminals for daily inventory checks. The team scanned the entire 5,000 square meter warehouse in just 10 minutes, compared to the whole day it took with manual methods.

Their RFID inventory tracking accuracy reached 99.9%, reducing inventory shrinkage and stock discrepancies.

3. RFID Inventory Tags in Outbound and Picking Operations

Outbound management is another area where RFID tags for inventory shine. When goods are ready for shipment, the system generates outbound orders based on the First-In-First-Out (FIFO) rule.

Here’s how it works:

- The RFID warehouse system guides the operator to the correct shelf.

- The worker uses an RFID handheld reader to locate the right items.

- The system verifies the goods in batches, eliminating the risk of wrong shipments.

When the goods pass through the outbound gate, RFID readers automatically check if the picked items match the order. If there’s a problem—like a missing product—the system will alert the operator.

Benefits of RFID in outbound management:

- Faster picking and packing

- Real-time data synchronization

- Reduced shipping errors

This method is essential for industries like e-commerce, where fast and accurate deliveries are critical.

4. Shelf Shifting and Warehouse Sorting with RFID Inventory Management

Another common challenge in an RFID warehouse is shelf shifting—moving goods from one storage location to another.

With RFID tags for inventory, workers scan the tag using a handheld RFID reader. The system updates the product’s new location in real-time, reducing the risk of lost or misplaced items.

In transit warehouse sorting, UHF RFID handheld terminals make the process even smarter. The terminal displays the status and location of each package and records every movement automatically. This eliminates manual paperwork and speeds up sorting in busy logistics hubs.

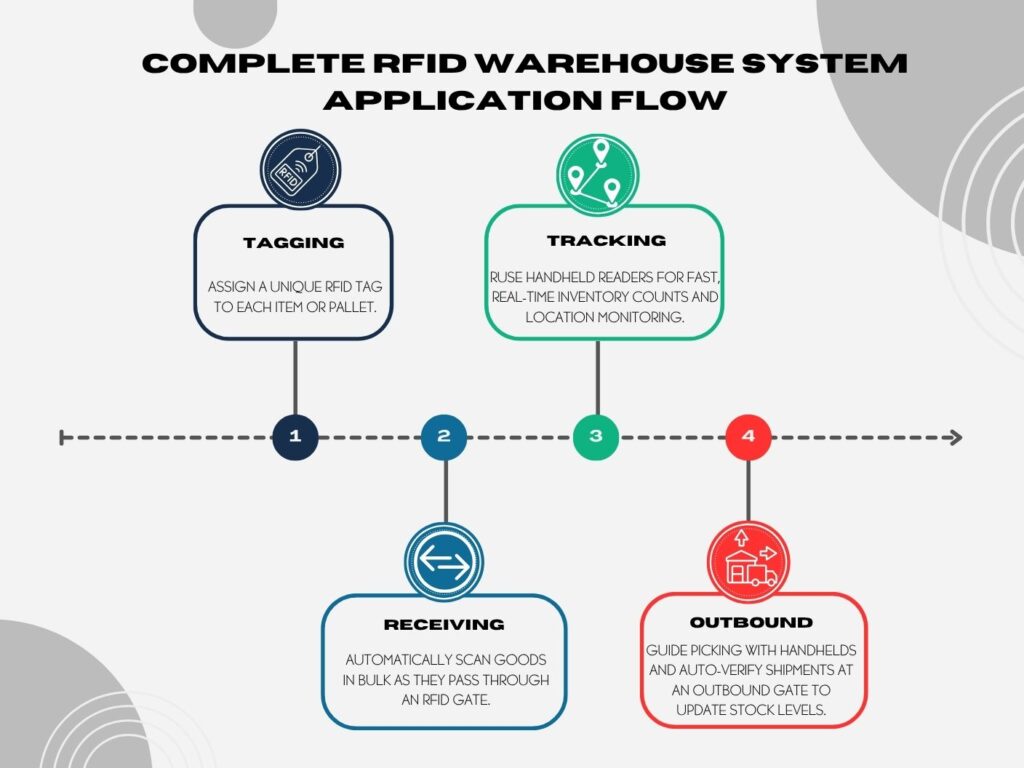

Complete RFID Warehouse System Application Flow

Let’s take a closer look at how an end-to-end RFID inventory management system works:

Step 1: Tagging Before Storage

- Use an RFID printer to create RFID inventory tags.

- Encode data like product name, batch number, and unique ID.

- Attach tags to each item or pallet.

Step 2: Automated Goods Receiving

- Goods pass through an RFID-enabled gate.

- RFID fixed readers scan all tags in bulk.

- The system matches data with the inbound order.

- If there’s a mismatch, an alarm is triggered.

Step 3: Real-Time Inventory Tracking

- Use RFID handheld readers for RFID inventory tracking.

- Perform full warehouse scans in minutes.

- Data is synchronized offline or in real time.

- Monitor low stock, expired goods, or misplaced items.

Step 4: Intelligent Picking and Outbound

- The system creates optimized picking routes.

- RFID handheld devices guide workers to the correct location.

- Goods pass through outbound RFID readers for final check.

- System updates inventory and generates reports automatically.

Real-World Results: The RFID Warehouse in Action

Case Study: RFID in a Logistics Hub in South China

A large warehouse in Guangzhou implemented RFID tags for inventory across their entire operation. Here’s what they achieved:

- 90%+ efficiency improvement in goods receiving and outbound processes.

- Reduced labor costs by eliminating manual scans.

- Improved RFID inventory tracking accuracy to nearly 100%.

- Automated shelf shifting and warehouse sorting.

- Real-time monitoring of product movements and stock levels.

- Automated alerts for expired, low stock, or missing goods.

They used a combination of RFID handheld terminals, fixed RFID gate readers, and software connected to their WMS.

Why RFID Inventory Tags Are the Future

The use of RFID tags for inventory is no longer optional for companies that want to stay competitive.

Whether it’s retail, manufacturing, logistics, or e-commerce, RFID is transforming warehouse operations. RFID inventory management is not just about tracking—it’s about optimizing every part of the supply chain.

Let’s summarize why businesses are choosing RFID tags for inventory:

- Speed: Scan hundreds of items at once, no line-of-sight needed.

- Accuracy: Eliminate human error with automated tracking.

- Real-Time Data: Always know your stock levels and item locations.

- Cost Savings: Reduce labor costs and avoid stock-outs or overstocking.

Conclusion

If you manage a warehouse or supply chain, investing in RFID inventory tags can help you take control of your operations. From inbound to outbound, shelf shifting, and inspections, RFID simplifies complex workflows and makes your warehouse smarter.

As the case studies above show, RFID inventory tags are already delivering real value to businesses worldwide.

By adopting RFID inventory management, you’ll improve efficiency, reduce costs, and stay ahead of your competitors.

Choose the Right RFID Tags for Your Inventory

Simplify your warehouse operations with the right RFID tags for inventory tracking. Contact us now to find the best RFID solution for your business needs.