Reliable Inventory Management with RFID on Metal Tag

Inventory Management with RFID: Smarter, Faster & More Reliable

Modern businesses need real-time control and visibility over their stock. Our advanced inventory management with RFID solutions transforms outdated tracking methods into streamlined, intelligent systems. With RFID tags for inventory, you can instantly scan, locate, and manage assets—without manual effort or barcode limitations.

Especially for environments with metal surfaces, our on metal RFID tags deliver the performance you need, where traditional RFID solutions fail. Whether you’re managing a warehouse, retail store, or distribution center, inventory management with RFID gives you the edge.

Why Use Inventory Management with RFID?

Traditional barcode systems require manual scanning and line-of-sight, making them slow and prone to human error. In contrast, inventory management with RFID allows you to:

- Read multiple items at once (bulk scanning)

- Identify inventory even if it’s hidden or stacked

- Eliminate miscounts and ghost inventory

- Make smarter decisions with real-time data

Our system includes specially engineered on metal RFID tags that stick to metal assets and shelving—ideal for industries like manufacturing, aviation, and logistics. Want to dive deeper into the benefits of RFID? Read: What is the RFID Inventory System?

Key Features of Our RFID Inventory Management Solutions

- High-Speed Bulk Scanning – Scan multiple items at once with no line of sight required.

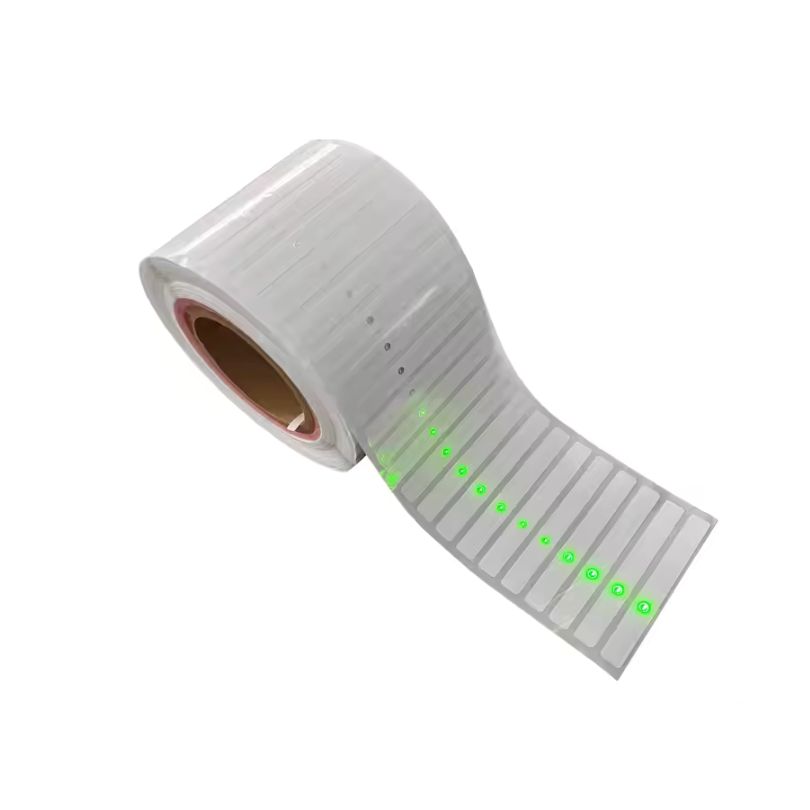

- On-Metal Compatibility – Our on metal RFID tags perform reliably on metallic surfaces and shelving.

- Real-Time Visibility – Get instant insights into inventory location, quantity, and status.

- Error Reduction – Eliminate manual entry and reduce stock discrepancies.

- Seamless Software Integration – Compatible with existing ERP and WMS systems.

- Durable RFID Tags – Our RFID tags for inventory are built to withstand industrial environments.

Implementing inventory management with RFID reduces operational costs, improves stock accuracy, and enhances decision-making across your entire supply chain.

Real Case

A global automotive parts manufacturer switched from barcode scanning to inventory management with RFID using our on metal RFID tags. Result?

- 65% reduction in time spent on inventory audits

- 30% decrease in inventory discrepancies

- ROI achieved in under 6 months

This client now tracks 15,000+ metal components across four warehouses in real time.

Technical Specifications

| Feature | Details |

|---|---|

| Frequencies | UHF (860–960 MHz), HF (13.56 MHz), LF (125–134 kHz) |

| Tag Types | Standard RFID tags, on metal RFID tags, rugged industrial tags |

| Materials | PET, paper, epoxy, or metal-compatible adhesive options |

| Read Range | Up to 10 meters (varies by tag type and environment) |

| Reader Compatibility | ISO 18000-6C and ISO 14443 compliant |

| Data Retention | 10+ years |

| Customization | Custom encoding, barcode printing, size, and chip options available |

Applications of Inventory Management with RFID

Our RFID solutions are suitable for many industries:

- Warehousing & Logistics: Track items across large facilities with ease.

- Retail Inventory: Improve shelf accuracy and speed up cycle counts.

- Manufacturing: Automate component tracking and reduce assembly errors.

- Healthcare & Labs: Track medical equipment and supplies with precision.

- IT Asset Management: Use RFID tags for inventory to monitor servers, laptops, and mobile devices.

- Industrial & Tools: Use on metal RFID tags for rugged asset tracking in factories and workshops.

Whether you’re scanning items in bulk or tracking high-value equipment, inventory management with RFID is the smarter solution.

Frequently Asked Questions (FAQs)

What is inventory management with RFID?

It’s the use of RFID technology to track and manage inventory automatically. RFID tags send data wirelessly to readers, enabling faster and more accurate stock control.

What are on metal RFID tags?

These are specialized RFID tags designed to work on metal surfaces, where normal tags fail due to interference.

How do RFID tags for inventory reduce errors?

They eliminate manual scanning and automatically record item movement, minimizing human error and missed scans.

Can RFID tags be reused?

Yes, many of our RFID tags for inventory are reusable and reprogrammable for long-term applications.

How do I choose the right RFID system?

It depends on your inventory size, materials (metal, plastic, etc.), read range needs, and environment. Our experts can help you choose the best solution.

Why Choose Us for Inventory RFID Solutions?

- RFID Experts – 10+ years in industrial-grade RFID development.

- Custom Tags – Tailored sizes, materials, frequencies, and branding.

- Seamless Integration – Compatible with your existing ERP or WMS systems.

- Quality Assured – ISO-certified factory with strict QA process.

- End-to-End Support – From tag selection to implementation training.

Ready to Upgrade Your Inventory System?

Make the move to smarter, faster, and more accurate operations.

Contact us today for a free consultation or custom quote for your inventory management with an RFID solution.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

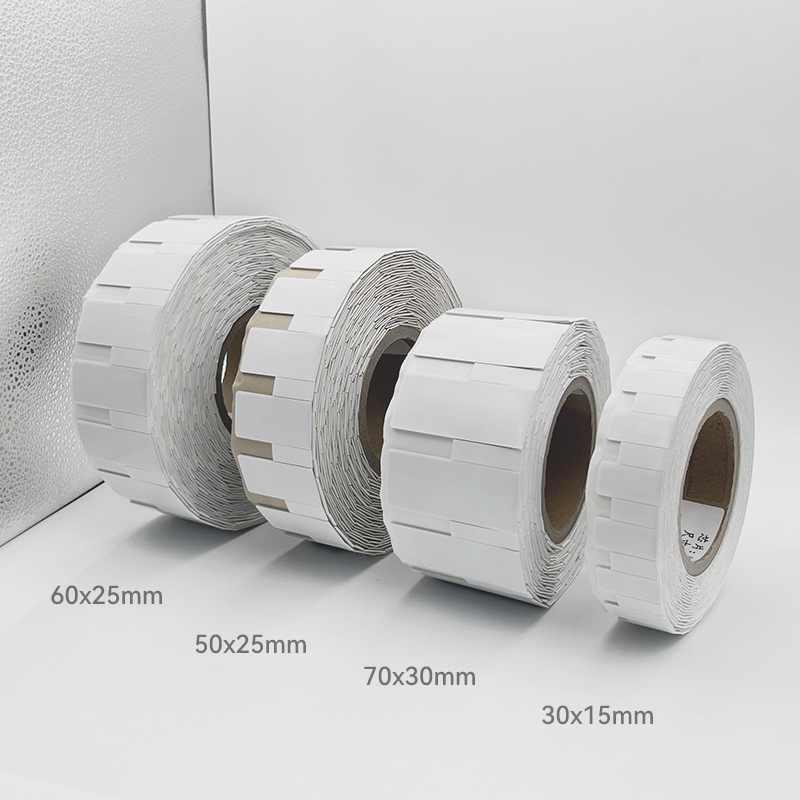

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.