| Feature | Description |

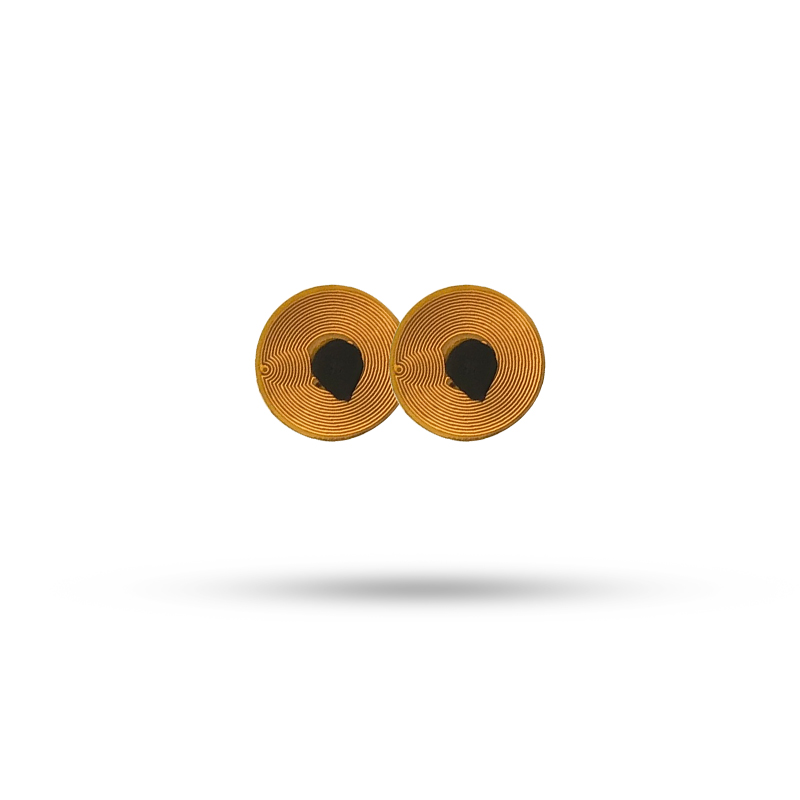

| Frequencies | UHF (860–960 MHz), NFC (13.56 MHz) |

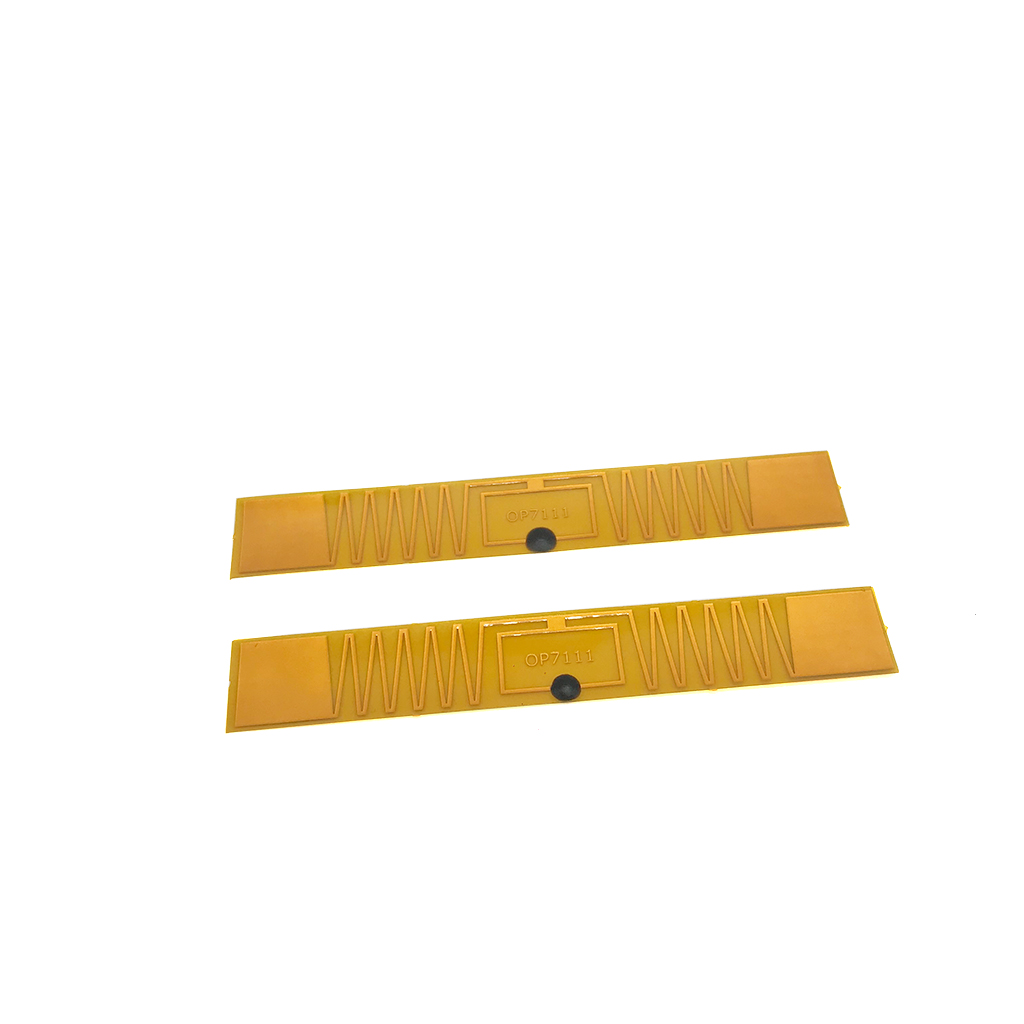

| Material | Polyimide & FPC construction |

| Operating Temperature | Standard: -40°C to 200°C; Custom: Up to 280°C |

| Adhesive Options | Industrial, heat-resistant, and epoxy-compatible adhesives |

| Compliance | ISO 18000-6C, RoHS, CE |

| Chip Compatibility | Alien, Impinj, NXP |

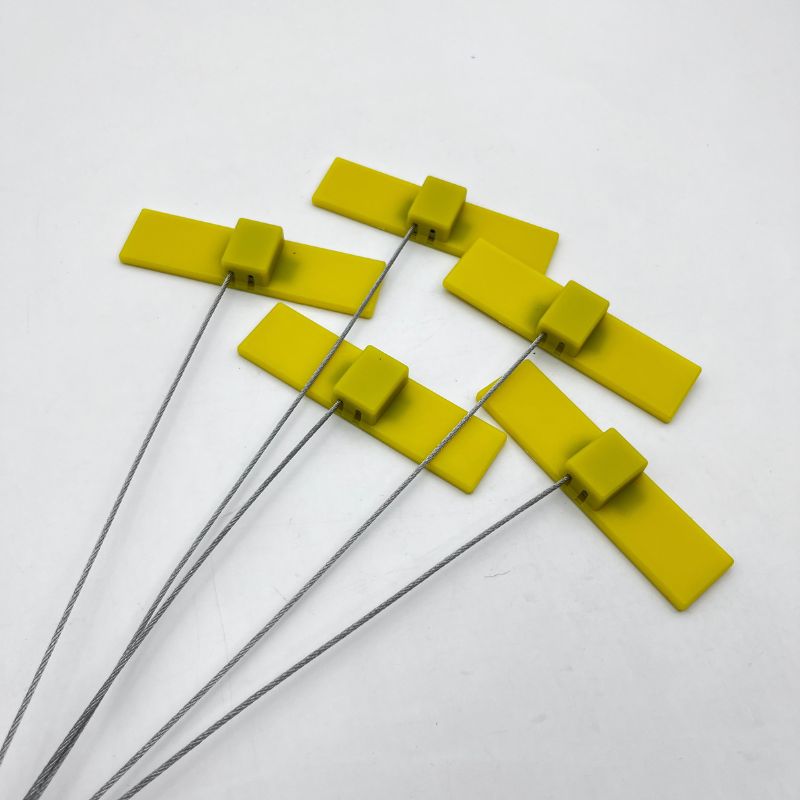

| Form Factors | Stickers, inlays, embedded modules |

High-temperature Tag RFID UHF FPC Waterproof Sticker

High-Temperature Tag RFID UHF | Flexible FPC RFID Tags for Harsh Environments

Our advanced Tag RFID UHF solutions are built for performance and resilience—especially in environments where standard RFID tags fail. Whether you’re managing assets in high-heat areas or embedding RFID into non-traditional surfaces, our FPC RFID Tags offer unmatched flexibility, durability, and precision.

Designed to excel in demanding industries like manufacturing, logistics, and automotive, these High Temperature RFID Tags ensure reliable identification and tracking—even in extreme conditions.

Key Features of Tag RFID UHF

Extreme Temperature Resistant

Withstand temperatures from -40°C to 280°C. Ideal for industrial ovens, tire tracking, and heavy-duty equipment.Flexible FPC Construction

Built with FPC RFID Tag technology, these stickers are ultra-thin, bendable, and perfect for embedding or curved surfaces.Superior Read Performance

Our Tag RFID UHF solutions provide long read ranges and quick data capture, even when applied to metal or heat-exposed surfaces.Advanced Chip Integration

Features high-performance chips like Alien H3 and Impinj Monza for accurate data transmission.Customizable Design

Available in various sizes, shapes, and adhesive types. Full printing and encoding services provided.ISO Compliant & Global Ready

Fully compliant with ISO standards and ready for deployment in international supply chains.

Real Case Application

Use Case: Tire Manufacturing Line

A global tire manufacturer integrated our High Temperature RFID Tags into its production line. The result?

Tags survived curing chambers over 250°C

99.9% scan accuracy during conveyor belt movement

Improved traceability and real-time stock updates across global plants

These Tag RFID UHF units eliminated manual tracking errors and increased operational efficiency by 65%.

Technical Specifications

Applications of Tag RFID UHF

Our Tag RFID UHF solutions are used in:

Supply Chain Management

Industrial Equipment Monitoring

High Temperature Production Lines

Inventory & Asset Tracking

Laboratory Instrument Tracking

Tire Tagging

Wherever durability, precision, and heat resistance are required, our FPC RFID Tags deliver top-tier performance.

Why Choose Our FPC RFID Tags?

- Expert Guidance: Work with RFID specialists to choose the right tag for your environment

- Custom Configurations: Full flexibility in shape, antenna, and data encoding

- Low Price Guarantee: Competitive pricing with no compromise on quality

- Free Samples Available: Test before you invest

- Seamless Integration: Works with standard RFID readers and software systems

Our High Temperature RFID Tags are engineered with one goal in mind: long-term, reliable tracking no matter the challenge.

Looking for an RFID solution that thrives where others fail?

Contact us today to get a custom quote or request a free sample of our high-performance Tag RFID UHF stickers. Experience the power of FPC RFID Tag technology designed for heat, pressure, and performance.

What makes a Tag RFID UHF suitable for high temperatures?

Our tags use polyimide and FPC construction that resists extreme temperatures, maintaining signal integrity and adhesive strength in harsh environments.

Can I embed these FPC RFID Tags into curved or flexible materials?

Yes, the FPC substrate is bendable and thin, ideal for embedding or application on non-flat surfaces.

What’s the typical read range?

Read range varies from 2 to 10 meters depending on tag size, reader strength, and surface material.

Do you offer custom printing and pre-encoding?

Absolutely. We can print barcodes, logos, and encode your data to suit your operation.

What’s the minimum order quantity?

MOQ typically starts from 100 pieces, depending on the customization. Contact us for details or bulk pricing.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.