High Temp RFID Tags Washable PPS Round Button Laundry Tag

Washable High Temp RFID Tags – PPS Button Laundry Tag for Extreme Heat & Industrial Wash Cycles

Built for the harshest laundry conditions, our Washable High-Temp RFID Tags are engineered to withstand extreme heat, moisture, and chemicals. Featuring a compact PPS round button design, these tags are ideal for industrial laundries, hospitals, and uniform services needing durable, long-lasting RFID solutions.

Made from heat-resistant PPS polymer and sealed with industrial-grade epoxy, each RFID button tag endures up to 250°C and 1,000+ industrial wash cycles. Whether you’re tracking linens or sterilizing medical textiles, our high temp laundry tags ensure precise and automated asset management.

Durability in Heat, Water, and Chemicals

Tested to meet ISO 6330 standards, these passive High Temp RFID Tags offer reliable performance in even the most demanding environments:

- Temperature Resistance: Operates from -40°C to +250°C

- Waterproof & Chemical-Resistant: Maintains function after hundreds of washes

- Metal Interference Shielding: Reliable reads near machinery or carts

- Built to Last: Over 1,000+ wash/dry/sterilization cycles

The encapsulated RFID chip complies with EPCglobal Gen2 protocol, enabling rewritable memory for dynamic asset updates.

Optimize Textile Operations Across Industries

These High Temp RFID Tags integrate with leading textile and uniform management systems to reduce human error and improve operational efficiency:

- Industrial Laundries

Track bulk laundry items like towels, bedsheets, and workwear in real time through RFID-enabled portals. - Healthcare Facilities

Ensure surgical drapes and gowns meet sterilization standards. Survive autoclave conditions without data loss. - Uniform Rental Services

Eliminate lost or misplaced uniforms using tamper-proof RFID tracking embedded directly in garments.

Compatible with major RFID readers including Zebra, Impinj, and HID Global, these tags help businesses reduce manual counting by up to 90% and achieve 99.9% inventory accuracy.

Technical Specifications of High Temp RFID Tags

| Feature | Specification |

| Material | PPS Polymer + Industrial Epoxy Seal |

| Operating Temperature | -40°C to +250°C |

| Frequency Range | UHF 860–960MHz (EPCglobal Gen2) |

| Read Range | Up to 10 meters |

| Wash Cycle Endurance | 1,000+ (ISO 6330 compliant) |

| Memory | 96-bit EPC + 512-bit user memory |

| Adhesive Strength | Embedded / Chemical-Resistant |

Why Choose Our RFID Laundry Button Tags?

- Long-Lasting Durability: No fading or degradation, even after years of use

- Global Compatibility: Integrates with industry-standard RFID systems

- Cost-Efficient: Reduces tag replacements and manual audits

- Sustainability-Ready: Supports textile lifecycle tracking for ESG compliance

Conclusion: Maximize ROI with Smart Textile Tracking

Say goodbye to premature label failures and tedious inventory checks. Our High-Temperature RFID Tags deliver unmatched durability and data precision, enhancing textile lifecycle management and sustainability compliance, including IntraLogisteX 2025 goals. Empower your industrial laundry or healthcare facility with rugged RFID performance that is as tough as your environment.

👉 Request a Free Sample Today or Contact Us to integrate these high-performance RFID laundry tags into your system!

FAQ

What are these RFID laundry tags used for?

They are designed to track textiles like linens, uniforms, and medical garments through harsh industrial laundry, sterilization, and autoclave processes.

How many wash cycles can these tags withstand?

These tags are built to endure over 1,000 industrial wash, dry, and sterilization cycles. They are also resistant to the harsh chemicals used in commercial laundries.

What is the maximum temperature these tags can handle?

The tags can operate in extreme temperatures from -40°C up to +250°C, making them perfectly suitable for high-heat drying and autoclave sterilization.

How are the tags attached to clothing and linens?

Their compact button design allows them to be discreetly and permanently sewn into the seams or hems of garments, uniforms, and other textiles.

How can these tags improve my operations?

By automating your tracking, you can significantly reduce manual counting, achieve near-perfect inventory accuracy (99.9%), prevent lost items, and ensure compliance with sterilization procedures.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

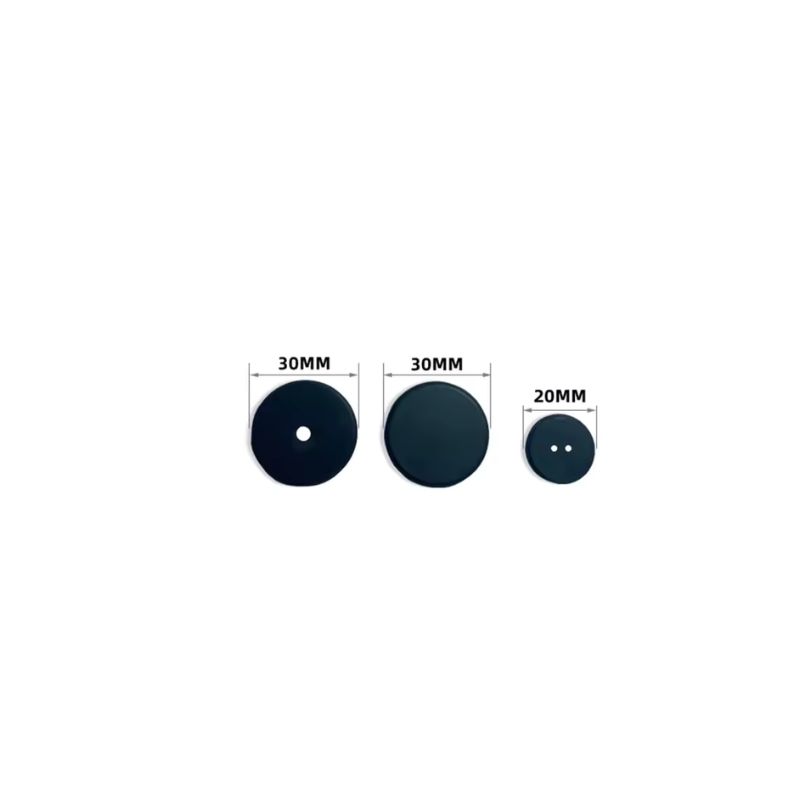

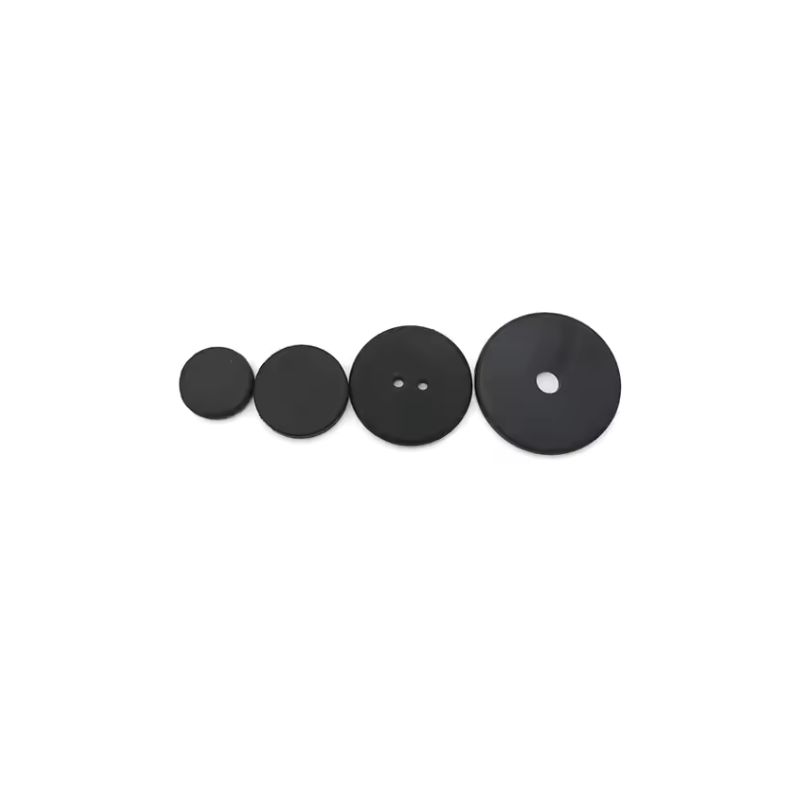

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.