Custom Smart Passive RFID Tags on Clothes Management

Custom Smart Passive RFID Tags on Clothes for Advanced Apparel Management

Managing inventory in today’s fast-paced apparel industry requires more than spreadsheets and barcode scanners. With shrinking margins, increasing competition, and rising theft risks, businesses need smarter systems to track, manage, and optimize their garment inventory.

Our custom smart passive RFID tags on clothes are designed specifically for fashion retailers, manufacturers, laundries, and logistics providers looking to automate operations, reduce losses, and gain full supply chain visibility — from production to point of sale.

Why RFID Tags on Clothes Are a Game-Changer

Traditional garment management systems are often plagued by:

- Manual entry errors

- Inventory shrinkage due to theft or misplacement

- Time-consuming audits

- Inability to track garments through laundering or logistics cycles

With our RFID-enabled solution, you gain:

- Real-time inventory visibility

- Loss prevention through automated tracking

- Supply chain transparency from source to store

- Actionable insights for demand forecasting & stock optimization

Key Benefits of Using RFID Tags on Clothes

Here’s what makes our RFID tags ideal for modern apparel operations:

- Real-Time Inventory Accuracy

Instantly locate and count every tagged garment — even in high-density environments like warehouses or retail backrooms. - Shrinkage Reduction

Prevent loss, theft, and misplacement with precise item-level tracking. - Efficient Stock Allocation

Move stock intelligently across locations to match demand and avoid overstock or stockouts. - Hands-Free Process Automation

Replace manual scanning and data entry with passive, automated RFID reads. - Durable & Wash-Resistant

Designed to survive commercial laundry and repeated handling without losing readability. - End-to-End Lifecycle Management

Track garments from manufacturing, QC, and shipping to POS and post-sale services (e.g., rental returns or repairs). - Seamless Integration

Compatible with leading apparel ERP, POS, and inventory platforms. Our experts support full implementation.

Technical Specifications

| Feature | Typical Specification |

| Frequency | UHF (860-960 MHz) or HF (13.56 MHz) |

| Protocols Supported | ISO 18000-6C (UHF), ISO 14443 (HF) |

| Read Range | Up to 8 meters (UHF), 1 meter (HF) — depending on environment |

| IC Types | Impinj Monza R6 / R6P, NXP UCODE 8, or customer-specified |

| User Memory | Up to 512 bits (custom-configurable based on chip) |

| Material | Washable fabric, PPS, TPU, or custom-engineered textiles |

| Mounting Options | Sewn-in, heat-sealed, pressure-sensitive adhesive |

| Laundering Resistance | Designed for 200+ commercial laundry cycles (ISO 6330 compliant) |

| Customization | Size, shape, branding, and IC configuration available |

Get Started with RFID Tags on Clothes Today

Ready to modernize your apparel management system? Our custom smart passive RFID Tags on Clothes allow you to monitor garments throughout their lifecycle—boosting accuracy, cutting costs, and improving customer satisfaction.

Contact our RFID specialists for personalized advice, sample requests, or bulk pricing. Let’s take your garment tracking to the next level!

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

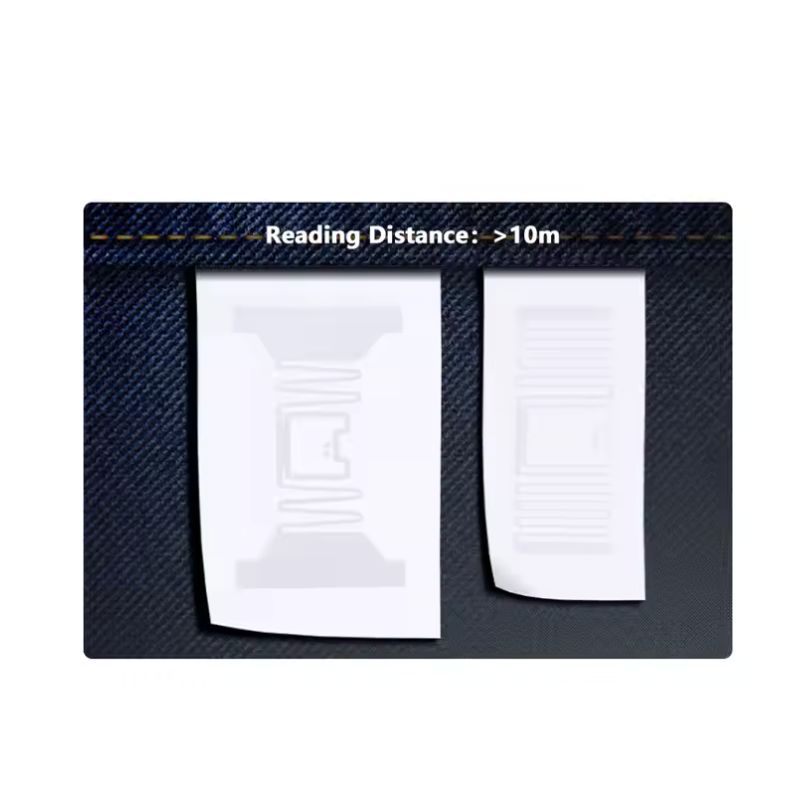

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.