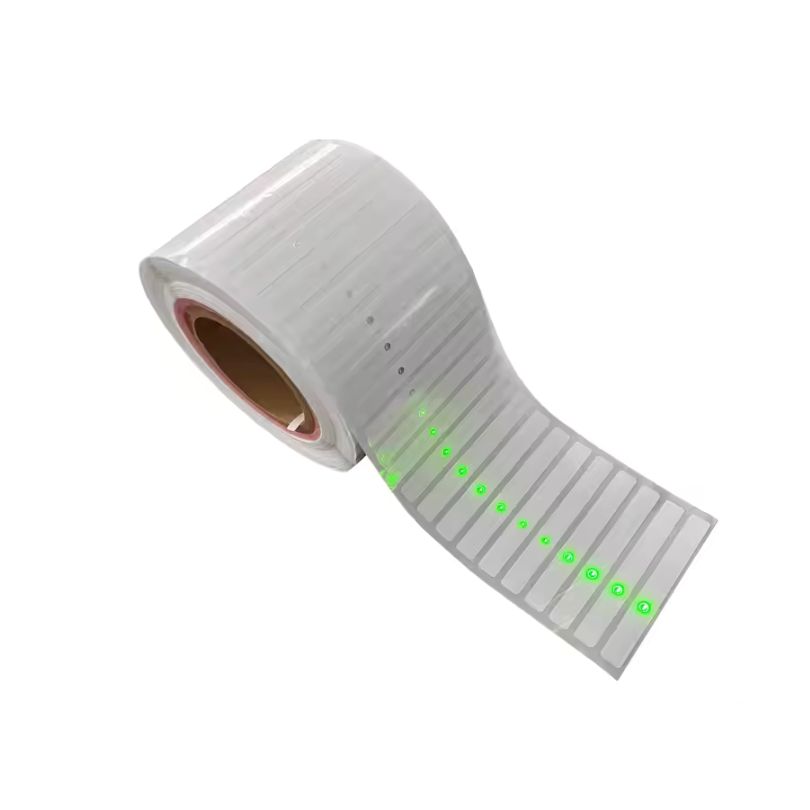

UHF RFID Metal Tag With Hole Fixing for Asset Tracking

Advanced UHF RFID Metal Tag: Simplified Solutions for Industrial Tracking

UHF RFID Metal Tag is engineered to address the challenges of tracking metal assets in demanding environments. Designed with reinforced anti-metal performance and integrated screw-hole fixing mechanisms, these tags deliver reliable data capture even on highly reflective surfaces like machinery, tools, and metal containers.

Their rugged construction and long-range capabilities make them indispensable for industries requiring precision and durability in asset management.

Key Benefits of UHF RFID Metal Tag

- Engineered for Metal Reliability: Anti-interference design ensures stable operation on metal surfaces.

- Durable & Versatile: Withstands harsh industrial environments (extreme temps/vibrations).

- Efficient Long-Range Scanning: Bulk asset tracking up to 9 meters, minimizing manual efforts.

Technical Specifications of UHF RFID Metal Tag with Hole Fixing

Below is a detailed breakdown of the tag’s core parameters, optimized for industrial-grade asset tracking:

| Parameter | Specification |

|---|---|

| RFID Chip | Alien Higgs or Impinj Monza (EPC Gen2 compliant) |

| Operating Frequency | 860–960 MHz (Global UHF) |

| Read Range | Up to 9 m with fixed readers |

| Mounting Mechanism | 2 pre-drilled holes for M5 screws |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Protection Rating | IP68 (Dustproof, waterproof up to 1.5m for 30 minutes) |

| Material | High-impact ABS with anti-corrosion coating |

| Dimensions | 50.5 mm diameter × 7.8 mm thickness |

| Memory | EPC: 128 bits, User Memory: 512 bits |

Applications Across Industries

UHF RFID Metal Tag excels in scenarios requiring secure mounting and high durability:

1. Heavy Machinery Management

Track excavators, cranes, and metal RTIs in construction and mining. The screw-hole fixing ensures tags remain intact despite vibrations and collisions.

2. Tool & Equipment Tracking

Monitor high-value tools in automotive workshops or aerospace facilities. The tags’ resistance to oils and solvents guarantees longevity in grease-heavy environments.

3. Logistics & Storage

Enable rapid inventory checks for metal pallets and shipping containers. Their long read range supports bulk scanning, reducing labor costs.

UHF RFID Metal Tags redefine durability and precision for industrial asset tracking. Combining anti-metal technology, screw-fastened security, and IP68 protection empowers businesses to maintain operational efficiency in the most challenging conditions.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.