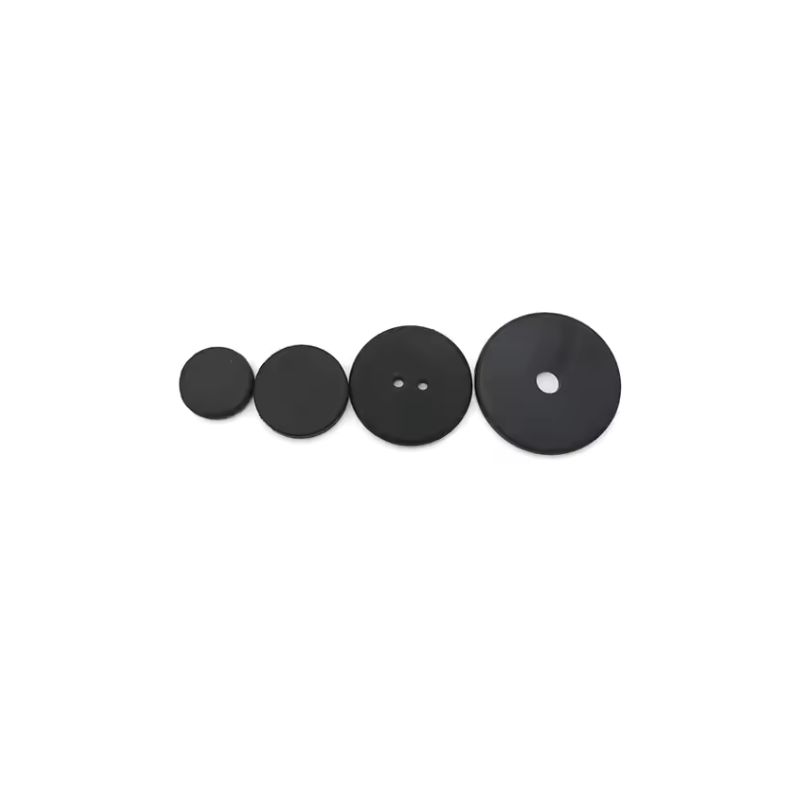

UHF Anti-Metal High Temperature RFID Tags for Tool Tracking

High Temperature RFID Tags | UHF Anti-Metal Tags for Tool Tracking in Harsh Environments

Tool tracking in harsh environments just got smarter. Our High-Temperature RFID Tags are engineered for industrial applications where heat, metal surfaces, and corrosive elements challenge traditional tracking solutions. These UHF Anti-Metal RFID Tags deliver durable, reliable performance even in temperatures up to 200°C, making them ideal for tool tracking in manufacturing, aerospace, oil and gas, and heavy equipment maintenance.

Overcome Harsh Conditions with High-Temp, Anti-Metal RFID Tags

Traditional RFID tags fail in high-heat, metal-heavy environments—ours don’t.

Our UHF Anti-Metal High Temperature RFID Tags are designed with advanced shielding and a rugged epoxy casing to withstand:

- Extreme Heat: Operate between -40°C to +150°C (up to 200°C for specialty models)

- Metal Interference: Engineered anti-metal structure ensures accurate reads on metallic surfaces

- Harsh Chemicals & Impact: Encapsulated in high-temp epoxy, rated IP68 for maximum protection

Stop losing track of your tools. With these Anti Metal RFID tags, you gain real-time visibility and full control of your industrial assets.

Why Choose Our High Temperature RFID Tags?

Implementing our tool tracking solution gives you measurable results:

- Real-Time Tool Location: Know where every tool is—instantly

- Loss & Theft Prevention: Accurate tracking discourages misuse or misplacement

- Effortless Inventory Audits: Streamline inspections with fast, automated scans

- Optimized Operations: Reduce downtime and improve tool utilization

- Enhanced Safety: Maintain compliance by tracking inspection and maintenance cycles

- Cost Efficiency: Lower labor, replacement, and audit costs with a durable RFID solution

Whether you’re tracking torque wrenches on a production line or power tools in a refinery, our High Temp RFID Tags offer industrial-grade dependability.

Technical Specifications

| Feature | Specification |

| Frequency | UHF 860–960 MHz |

| Operating Temperature | -40°C to +150°C (up to +200°C optional) |

| Read Range (On Metal) | Up to 8 meters (varies by reader/environment) |

| Chip Type | Impinj Monza 4QT |

| Data Retention | 10 years |

| Encapsulation | High-Temperature Epoxy |

| IP Rating | IP68 (Waterproof & Dustproof) |

| Mounting Options | Adhesive, Screw Mount, or Weldable |

Ready to Transform Your Tool Tracking?

Say goodbye to manual audits, lost tools, and unreliable labels. Our High-Temperature RFID Tags are trusted by top-tier industrial operations worldwide for their resilience, performance, and precision.

Contact us now to explore bulk pricing, get implementation advice, or request a sample. Let our RFID experts help you future-proof your tool-tracking system.

FAQ

What makes these RFID tags different?

They are specifically designed for harsh industrial use. They work on metal, resist extreme heat (up to 200°C), and are protected by a rugged, waterproof (IP68) epoxy shell.

What is the maximum temperature these tags can handle?

They operate from -40°C to +150°C. Specialty models are available that can handle up to +200°C.

What is the read range on metal tools?

Up to 8 meters (26 feet). The exact range depends on your specific RFID reader and environment.

How are the tags attached to tools?

You can attach them using industrial adhesive, screws, or by welding them directly onto the asset.

How can these tags improve my business?

They help you prevent tool loss, speed up inventory audits, reduce downtime, enhance safety, and lower operational costs.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.