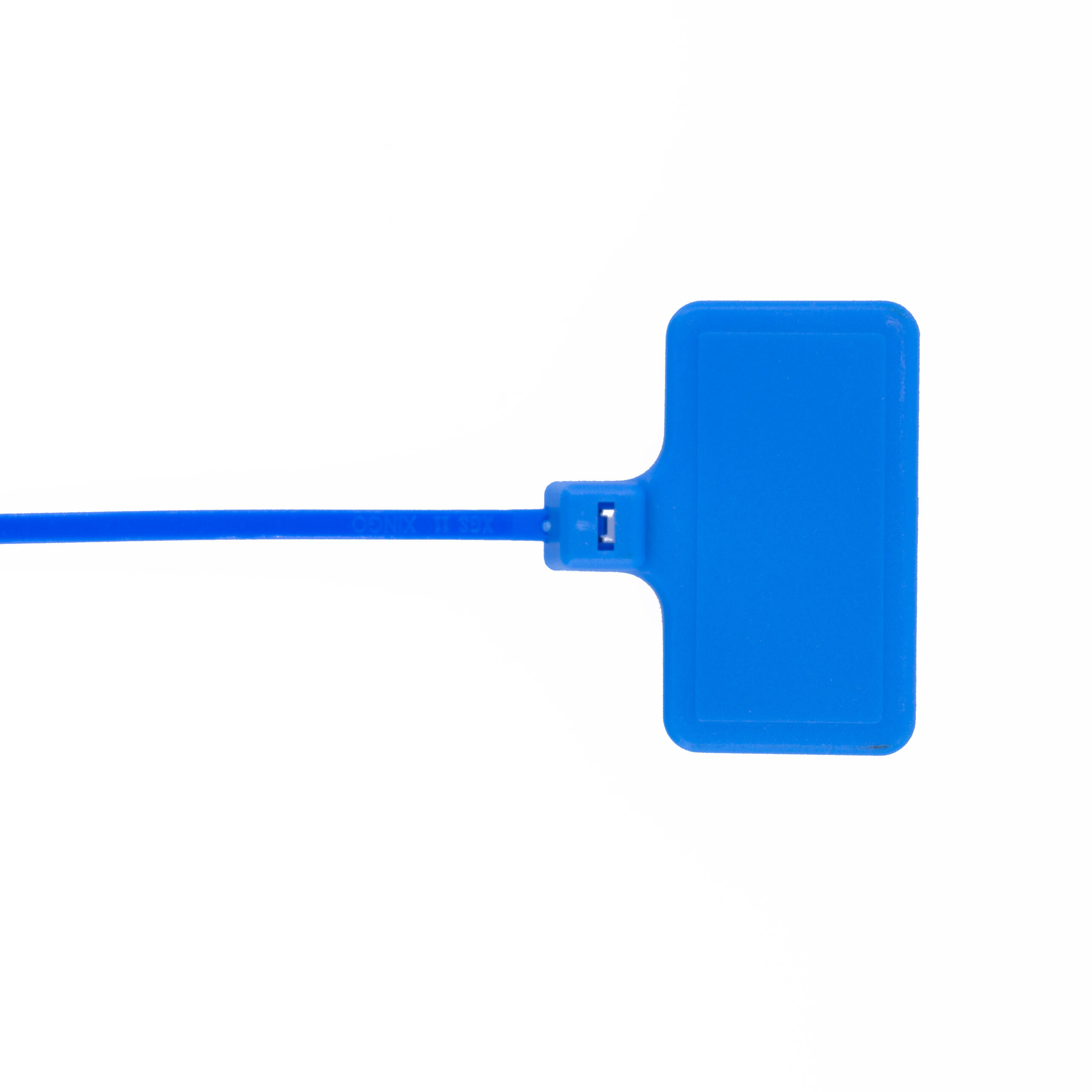

Trackable RFID UHF Seal Tag Freight Label Tie

RFID UHF Seal Tag – Smart, Secure, and Trackable Freight Protection

Protecting your cargo from tampering and theft is critical in high-value logistics. Our RFID UHF Seal Tag is a game-changing solution that combines the physical strength of a tamper-evident Seal Tag with the digital intelligence of RFID tracking. Engineered for global shipping and supply chain transparency, this RFID Seal Tag provides secure closure and remote visibility of your cargo status—all in one device.

Whether you’re managing cross-border shipments, sealed containers, or sensitive goods, our RFID UHF Seal Tag ensures a tamper-proof chain of custody, reduces loss, and helps you meet compliance with modern logistics standards.

Key Features of the RFID UHF Seal Tag

- Tamper-Evident Physical Seal – Each tag includes a unique, laser-etched ID and cannot be reused

- UHF RFID Technology (860–960 MHz) – Enables real-time tracking up to 8 meters

- Dual Security – Combines mechanical sealing and digital verification

- Durable Material – Polypropylene/Nylon alloy construction with IP67 waterproof rating

- Impinj Monza 4QT Chip – Ensures high memory performance and signal strength

- Custom Printing Available – Barcode, QR code, serial number, or logo

- Extreme Temperature Range – Operates from -40°C to +85°C for global freight conditions

Every RFID UHF Seal Tag comes pre-programmed and ready to use, with customization options for size, encoding, and printing.

Real Case Study: Securing High-Value Shipments in Latin America

A logistics company in South America was experiencing significant cargo tampering issues during freight transit. After switching to our RFID Seal Tags, they implemented real-time monitoring at checkpoints, reducing tampering events by over 70% in three months. The RFID UHF Seal Tag gave them unmatched visibility, enhanced accountability, and peace of mind throughout their network.

Technical Specifications

| Feature | Specification |

| RFID Protocol | EPC Gen2 (ISO 18000-6C) |

| Frequency | UHF (860–960 MHz) |

| Read Range | Up to 8 meters |

| Chip Type | Impinj Monza 4QT (or equivalent) |

| Memory | 128 bits EPC, 512 bits User Memory |

| Material | High-strength Polypropylene/Nylon |

| Tensile Strength | > 250 kg |

| Temperature | -40°C to +85°C |

| Waterproofing | IP67 rated |

| Printing | Laser Engraving (Barcode/Serial Number/Logo) |

| Dimensions | 80 x 30 x 10 mm (customizable) |

| Unique ID | Pre-programmed, unalterable |

Application Scenarios for RFID UHF Seal Tag

- Freight Containers & Trailers – Secure transport doors and seal verification

- Industrial Equipment Shipments – Prevent access to high-value machinery

- Air Cargo & Palletized Shipments – Enable smart handling and tracking

- Cross-Border Logistics – Comply with customs and border security protocols

- Last-Mile Delivery – Assure clients that goods arrived untampered

Whether you need a single-use Seal Tag for compliance or a smart RFID system for fleet logistics, this RFID Seal Tag is the optimal choice.

Why Choose Us?

We are a trusted global manufacturer of RFID Seal Tags tailored to industrial and logistics needs. Here’s why industry leaders rely on us:

- Full Customization – We customize chips, sizes, printing, and data encoding

- Industrial-Grade Manufacturing – Built for rugged supply chain use

- Fast Prototyping – Delivery in days, not weeks

- Worldwide Support – Logistics solutions for every region

- Expert Consultation – RFID deployment help for hardware and software

Join hundreds of logistics leaders using our RFID UHF Seal Tag to elevate their cargo security and compliance.

Secure, Track, and Verify your shipments in real-time with RFID UHF Seal Tag solutions.

FAQ

What is a RFID UHF Seal Tag?

It’s a tamper-proof physical security seal embedded with a UHF RFID chip, used to track and verify shipments in real time.

Can RFID Seal Tags be reused?

No. These Seal Tags are designed for single use only, and any removal results in visible tampering, ensuring security.

What’s the read range of your RFID UHF Seal Tags?

Typically up to 8 meters depending on the reader and surrounding environment.

Are these tags customizable?

Yes. We offer full customization for chip type, memory size, dimensions, colors, serial printing, and packaging.

Are these tags waterproof?

Absolutely. Our RFID UHF Seal Tags have an IP67 rating and are built for harsh environments, including rain and dust exposure.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.