Related Blog

Great things in business are never done by one person. They’re done by a team of people. We have that dynamic group of peoples

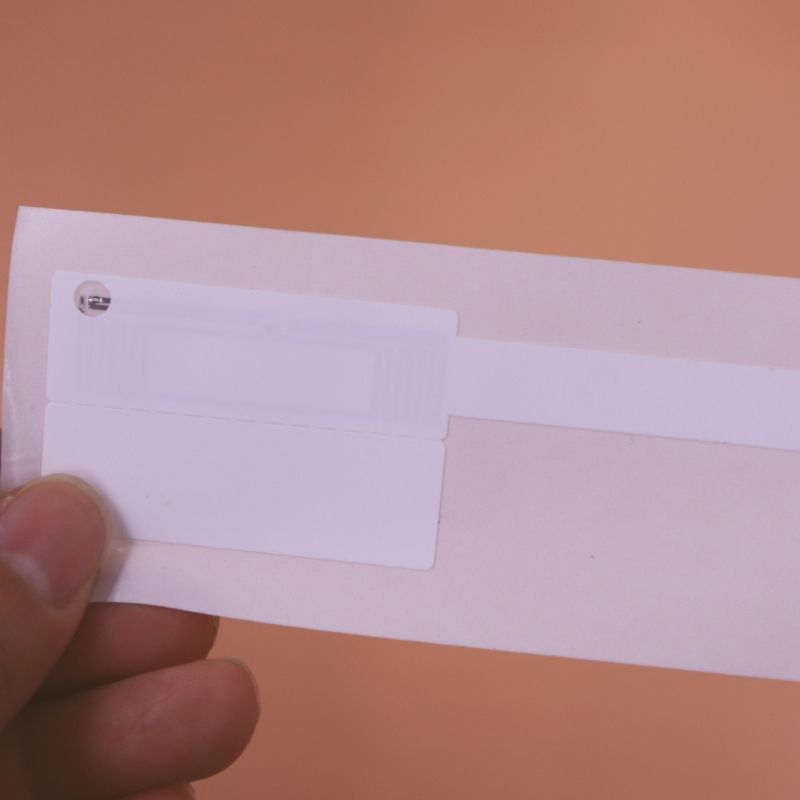

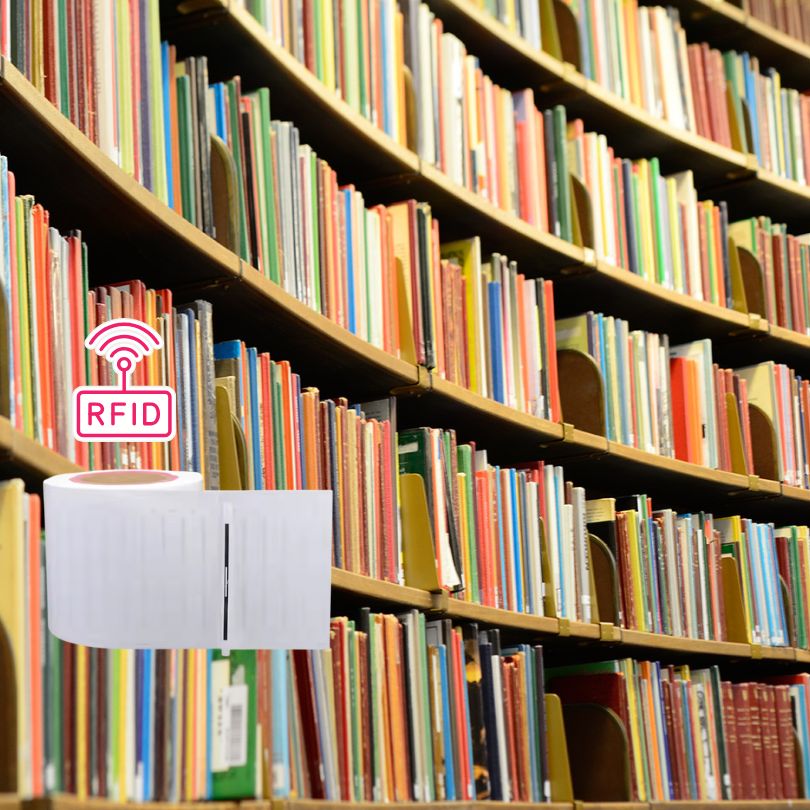

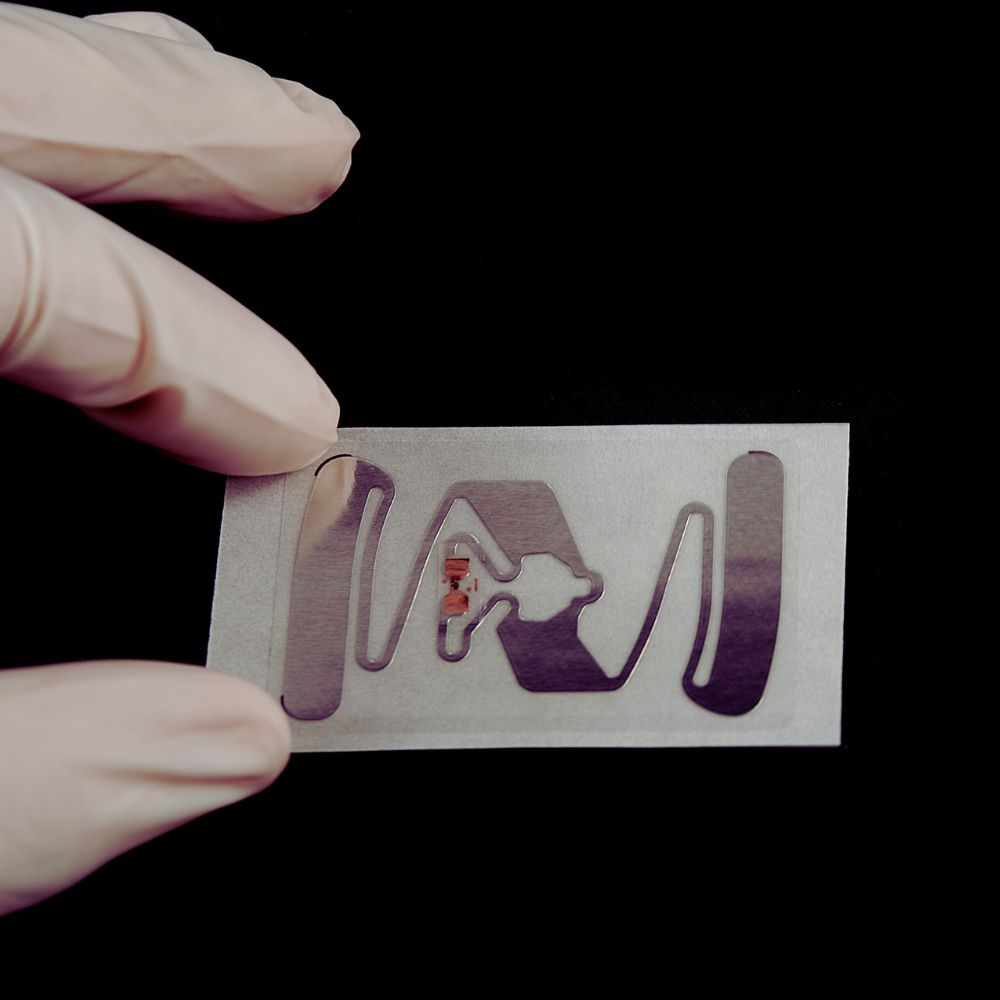

What Does RFID Mean

RFID, or Radio Frequency Identification, is a technology rapidly transforming industries. While you might not see it, RFID works behind the scenes, enhancing efficiency and security in everything from your local retail store to global supply chains.

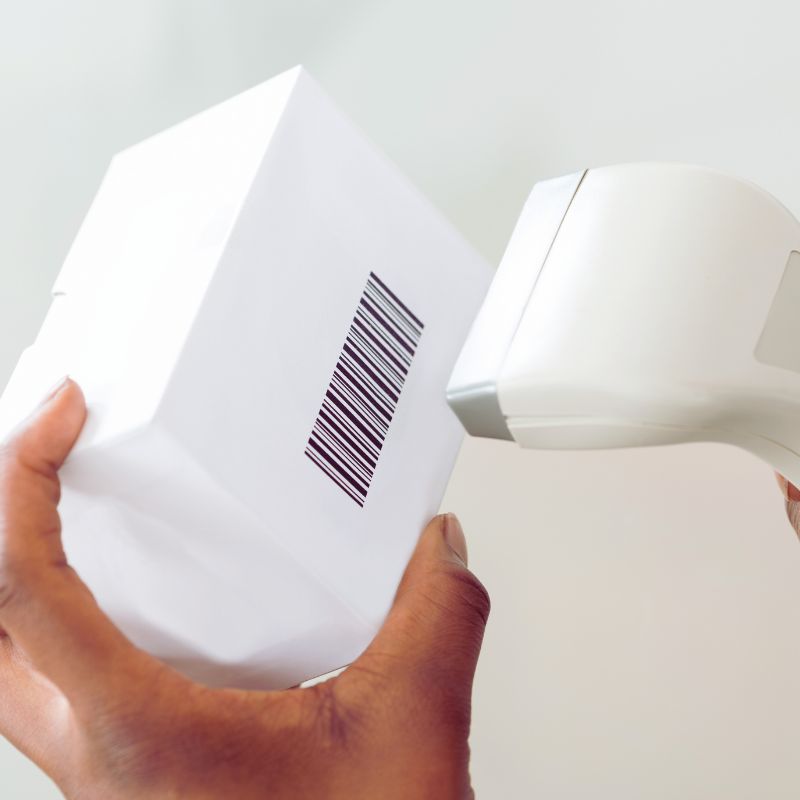

How Does RFID Tag Work in a Warehouse

In the modern world of warehouse and inventory management, harnessing the power of RFID technology can automate time-consuming processes, making your entire operation more seamless and profitable.

How Does Radio Frequency Identification Work

This article explores the transformative power of Radio Frequency Identification (RFID) technology across various sectors.