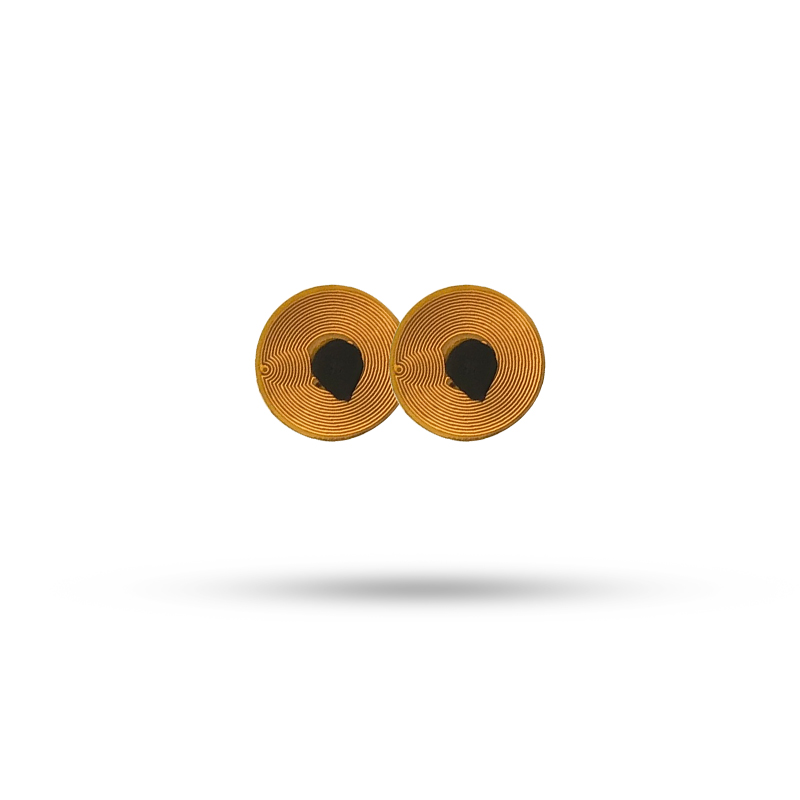

Passive Programmer RFID UHF Tags Label Chips Asset Tracking

High-Performance RFID UHF Tags : Revolutionizing Your Tracking and Inventory Management

Our cutting-edge UHF RFID tags offer an unparalleled solution for businesses looking to enhance their tracking and inventory management processes. These tags, leveraging radio frequency identification, provide superior performance and reliability and are designed to boost operational efficiency and reduce costs.

With our innovative products, we’ll show you that adopting advanced technology’s advantage is easier than ever. Discover how our UHF RFID tags can transform your operations!

Superior RFID UHF Tags Technology

RFID UHF Tags technology, operating within the ultra-high frequency range, offers a significant advantage over other types of RFID. These tags, often within the 860-960 MHz range in the U.S. and internationally, deliver a longer read range than HF or LF tags.

Using radio waves for data transfer and identification eliminates the need for line-of-sight scanning, making it perfect for tracking items on pallets, within warehouse shelves, and throughout the supply chain. Unlike active RFID tags that rely on internal power, our passive RFID tags do not need batteries, which increases durability and lowers the cost of maintenance.

Our UHF RFID tags are widely used in various applications and industries because of their exceptional performance and operational efficiency. Reading multiple items instantly allows for real-time tracking and faster data transfer rates, which improve workflow efficiency.

Streamlining Inventory Management with RFID

Implementing an RFID system using our RFID UHF Tags will revolutionize your inventory management processes. Traditional barcode systems often require manual scanning, which can be slow and prone to errors. With our RFID tag technology, you can instantly scan hundreds of items without needing direct visibility. This means faster inventory counts, reduced human error, and more accurate data, giving you complete control over your stock.

RFID allows for real-time tracking and monitoring of goods, leading to significantly more efficient supply chain management and reduced operational inefficiencies. With our tags, you can monitor inventory throughout your business, ensuring you always have accurate stock levels and can fulfill customer orders on time. This enhanced inventory management not only saves time and resources but also improves your overall operational productivity.

Versatile Applications of UHF RFID Tags

The application of RFID UHF Tags is extremely broad and adaptable, making them an ideal solution across various sectors, including retail, logistics, healthcare, aviation, and pharmaceuticals.

The versatility of our UHF RFID tag provides you with multiple types of RFID tags, each designed to fit a specific application. From asset tracking in industrial environments to garment tracking in retail stores, our tags can easily handle the job. For example, our tags can be used in the healthcare industry for patient tracking and medical equipment identification, ensuring efficient operations and data integrity.

In logistics, these tags streamline the movement of packages and goods, ensuring they reach their destination faster and more reliably. Our tags can work on almost any surface with an adhesive backing for easy attachment. They are durable and provide consistent performance even in harsh industrial environments. Choose our RFID products and achieve true efficiency.

Technical Specifications:

| Feature | Specification |

| Frequency | 860-960 MHz |

| Type | Passive UHF RFID |

| Read Range | Up to 10 meters (depending on the reader and environment) |

| Data Storage | Varies based on tag type |

| Operating Temp | -40°C to +85°C |

| Compliance | ISO 18000-6C, EPC Gen2 Compliant |

| Material | Durable, weather-resistant materials |

| Adhesive | Strong, pressure-sensitive adhesive |

| Data Retention | Minimum 10 years |

Usage Instructions:

Select the appropriate RFID tag: Ensure the tag is suitable for your specific business needs and operating environment.

Attach the tag: Remove the backing and affix the tag securely to the surface of the item you are tracking.

Encode the tag: Use an RFID printer and handheld reader to encode the tag with relevant information, such as product identification and serial number.

Implement tracking system: Integrate the data from the RFID tags into your tracking systems for real-time monitoring.

Monitor and manage: Utilize the data to improve inventory control, asset tracking, and overall operational efficiency.

Environmental Impact:

Our passive UHF RFID tags are manufactured with sustainability in mind. Their durable design and lack of batteries mean reduced waste and a smaller environmental footprint. The use of non-toxic materials and eco-friendly processes further minimizes our impact on the environment.

Why Choose Our UHF RFID Tags?

High Performance: Our tags offer a superior read range and faster data transfer rates than other RFID solutions.

Cost-Effective: Passive tags eliminate the need for batteries, reducing costs and maintenance.

Versatile: Suitable for a wide range of applications across various industries.

Improved Efficiency: Streamline your operations and improve productivity with real-time data and automation.

Enhanced Accuracy: Eliminate manual errors with automatic data capture.

Exceptional Durability: Our tags are designed for long-lasting performance.

Contact us today for free samples and explore the many advantages our UHF RFID tags can bring to your business.

Get Your Custom RFID Tags

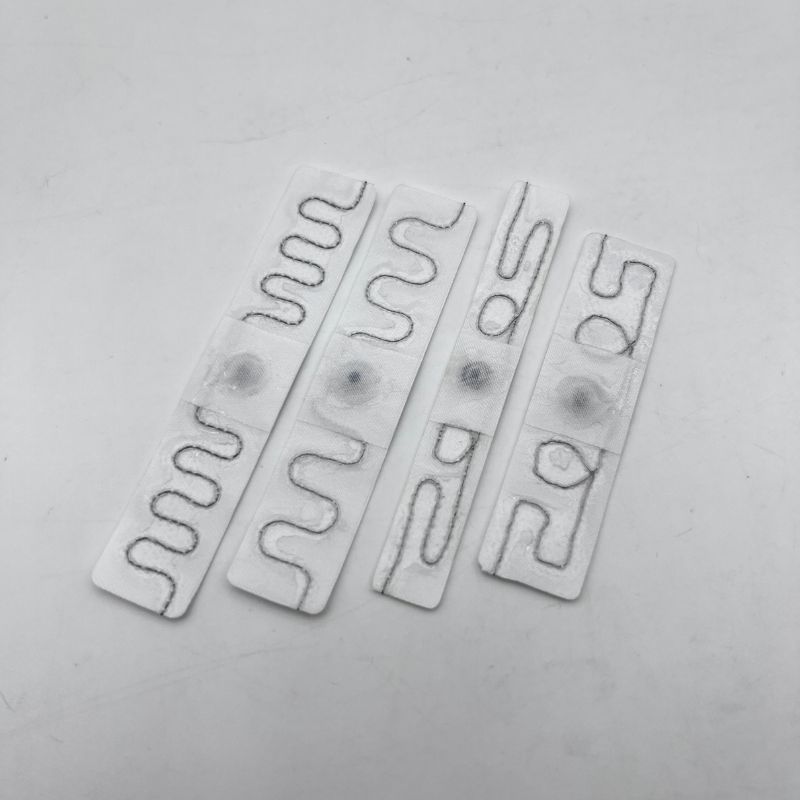

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.