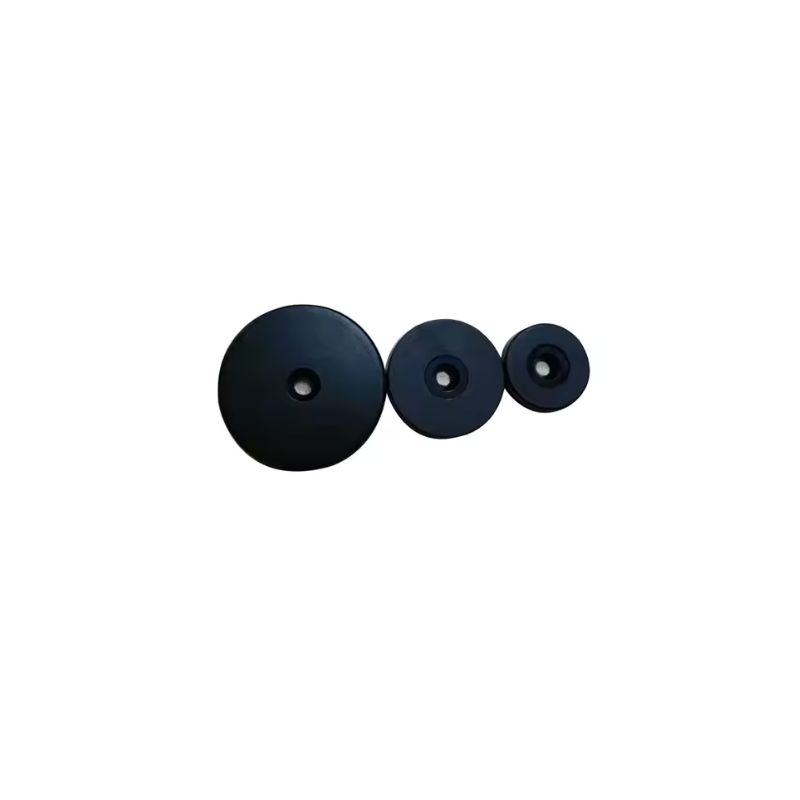

Long Range Passive RFID Tag Asset Tracking Anti-Metal Tag

Long Range Passive RFID Tag for High Temperature & Metal Environments

Track your assets in the toughest industrial conditions with our Long Range Passive RFID Tags. Built for durability and performance, these RFID tags are engineered to withstand high temperatures and metal interference—making them the go-to choice for industries like automotive, aerospace, manufacturing, and oil & gas.

Whether you’re managing parts in a paint booth or equipment in a furnace, our anti-metal, high-temperature RFID tags deliver long-range accuracy and rugged performance.

Why Choose Our Passive RFID Tags for Harsh Environments?

Traditional tags fail where ours excel. Our Long Range Passive RFID Tags are specifically designed for:

- Reliable long-range scanning up to 8 meters.

- High temperature resistance up to 200°C

- Anti-metal performance when mounted on metallic surfaces

- Battery-free passive operation for low maintenance and long life

- Chemical resistance against oils, acids, and solvents

These tags ensure uninterrupted asset tracking even in the harshest industrial settings.

Key Features of Our Long Range Passive RFID Tags

- Extreme Heat Resistance – Withstands up to 200°C+

- Long Read Range – Up to 8 meters, depending on environment

- Anti-Metal Design – Performs on metallic assets

- Passive UHF Technology – No batteries required

- Customizable Sizes & Mounting – Available in ceramic, PPS, Teflon

- Durable & Waterproof (IP68) – Resistant to chemicals and harsh weather

- Flexible Mounting – Screw, adhesive, welding, or custom setups

Applications of High Temperature Passive RFID Tags

Our rugged RFID tags are trusted in industries that demand durability and precision:

- Automotive Manufacturing – Track parts through painting and heat treatments

- Aerospace – Monitor components during high-temperature operations

- Oil & Gas – Tag equipment in extreme outdoor conditions

- Industrial Tools & Machinery – Real-time tracking in production lines

- Healthcare – Sterilize and reuse RFID-tagged medical equipment

- Logistics & Asset Tracking – Maintain visibility in complex supply chains

Technical Specifications

| Feature | Specification |

| RFID Protocol | EPC Class 1 Gen 2 / ISO 18000-6C |

| Frequency | 860–960 MHz (UHF) |

| Chip Type | Impinj Monza 4QT, NXP UCODE G2iM |

| Read Range | Up to 8 meters |

| EPC Memory | 96-bit to 512-bit |

| User Memory | Up to 2048 bits |

| Operating Temp | ’-40°C to +200°C |

| Survival Temp | ’Up to +220°C |

| Material Options | Ceramic, PPS, Teflon |

| IP Rating | IP68 or higher |

| Mounting | Screw, adhesive, weldable |

| Sizes | 10mm–50mm (customizable) |

| Chemical Resistance | Acids, solvents, oils |

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.