Blog correlati

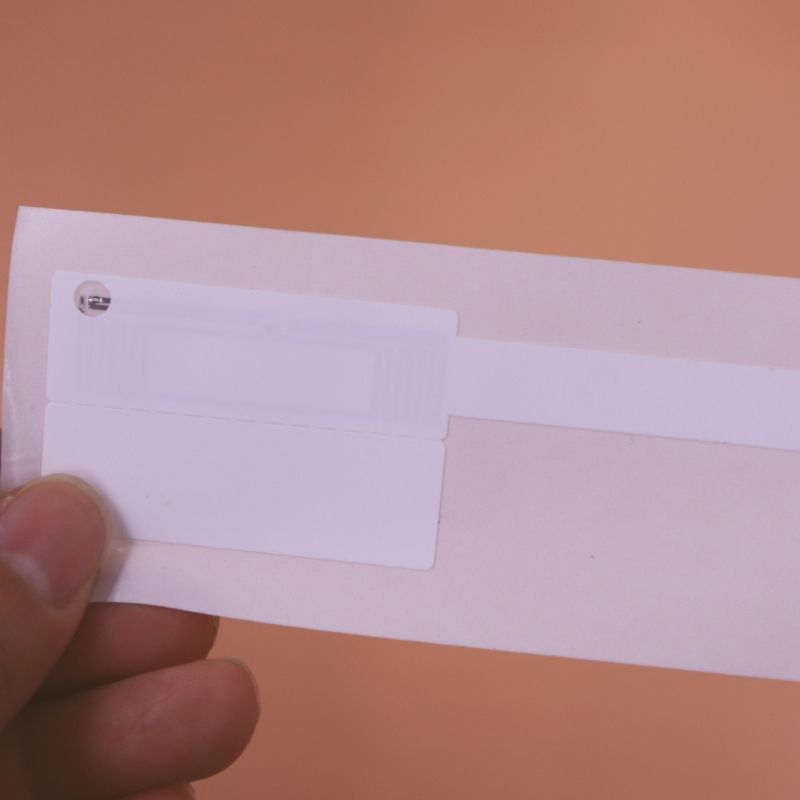

Come funziona il monitoraggio delle risorse RFID

Questo articolo approfondisce il tema del monitoraggio RFID delle risorse, una soluzione di monitoraggio all'avanguardia che sta trasformando la gestione dei beni di valore da parte delle aziende.

Come funziona l'identificazione tramite radiofrequenza

Questo articolo esplora il potere trasformativo della tecnologia di identificazione a radiofrequenza (RFID) in vari settori.

Che cosa è un portafoglio RFID

Questo articolo approfondisce il mondo dei portafogli RFID e della tecnologia di blocco, verificando se questi portafogli specializzati siano necessari per proteggere le tue carte RFID da scansioni non autorizzate e furti di identità.