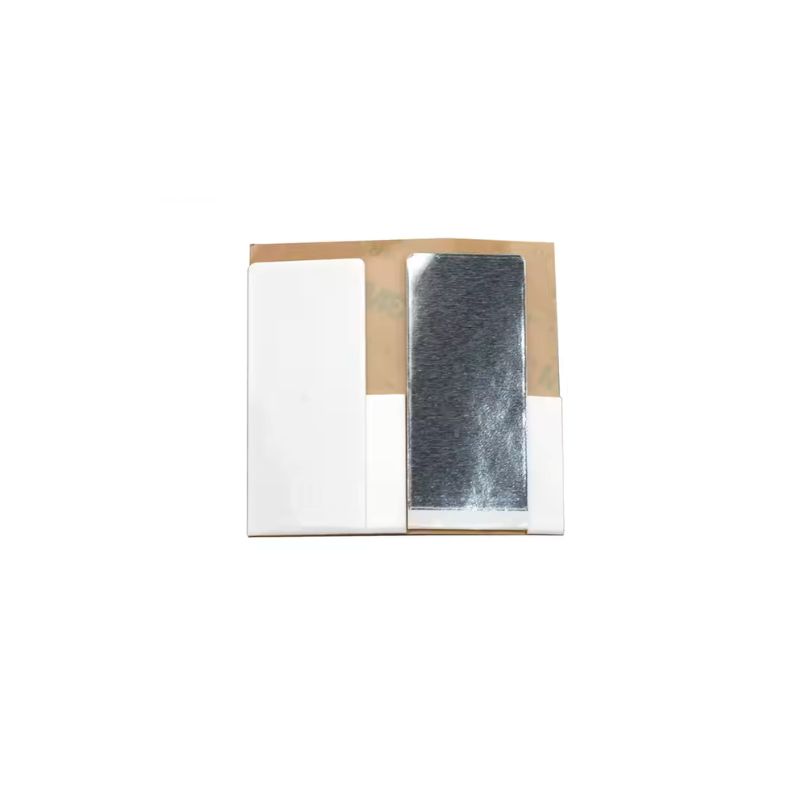

Flexible UHF RFID On Metal Label for Asset management

Seamless Asset Tracking with Flexible UHF RFID on Metal Labels

Managing and tracking metal-based assets across industrial environments has never been easier. Our Flexible UHF RFID on metal label is designed for reliability, flexibility, and long-range readability—delivering powerful performance where traditional RFID tags fail. Whether you’re overseeing pipelines, tools, vehicles, or IT assets, this label is purpose-built to stick to metal and stay readable, no matter the conditions. If you’re looking for a proven solution to upgrade your asset management strategy, this is the UHF RFID on metal tag to trust.

Key Features of the Custom 25mm RFID on Metal Label

- Optimized for Metal Surfaces: Explicitly built for steel, aluminum, and other metals.

- Flexible Construction: Bends easily around curved surfaces—perfect for pipes, cylinders, and irregular shapes.

- Extended Read Range: Up to 6 meters on metal, thanks to high-gain UHF antenna design.

- Industrial-Grade Durability: IP68-rated for water and dust protection, plus resistance to oil and extreme heat.

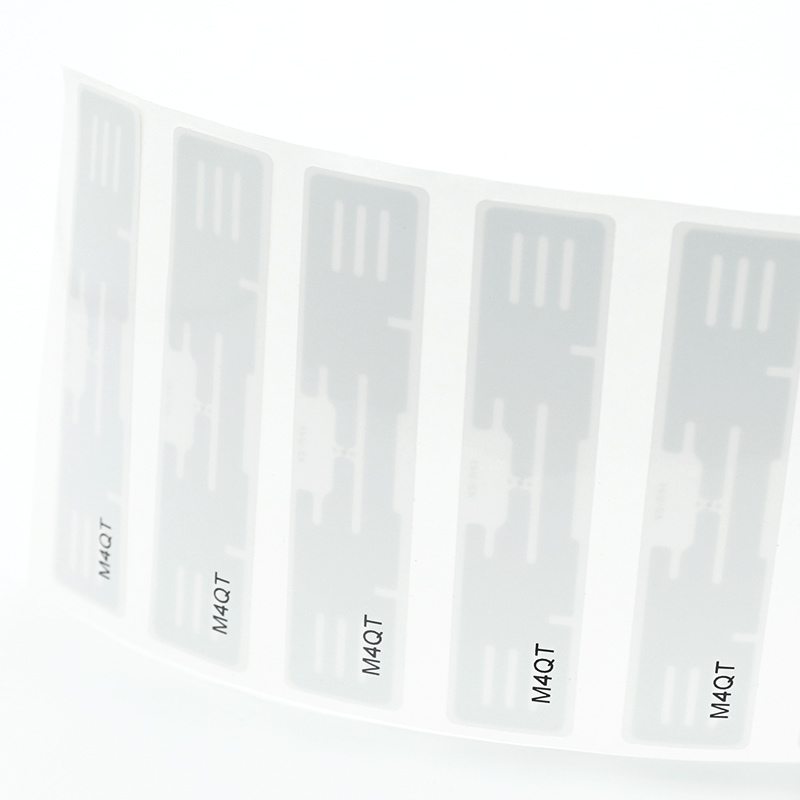

- Thermal Transfer Printable: Easily encode and label using standard UHF RFID printers.

- High Adhesion: Strong, long-lasting adhesive sticks firmly to rough or smooth metal.

Engineered for consistent signal clarity and long-term use, this RFID on metal label is your go-to for reliable asset visibility.

Real-World Applications

1. Manufacturing Plants

For efficient maintenance tracking, tag industrial machines, steel molds, or metallic components.

2. IT & Data Centers

Apply the On Metal UHF Label to server racks, metal cabinets, or equipment for streamlined audits.

3. Logistics & Warehousing

Label metal crates, containers, and vehicles to automate check-ins, inventory, and outbound processes.

4. Energy Sector

Track pipes, valves, and drilling tools in oil, gas, and renewable energy projects.

5. Government & Military Assets

Ideal for defense-grade inventory and mission-critical equipment tagging under extreme conditions.

UHF RFID on metal in each scenario unlocks operational efficiency and traceability across your supply chain or facility.

Technical Specifications: Flexible UHF RFID on Metal Label

| Feature | Specification |

| RFID Technology | UHF RFID on Metal (860–960 MHz) |

| Standards Compliance | EPCglobal Class 1 Gen2, ISO 18000-6C |

| Read Range (on metal) | Up to 6 meters (varies by environment & reader) |

| Material | PET/Polyimide with flexible anti-metal substrate |

| Dimensions | 95mm x 25mm x 1.2mm (custom sizes available) |

| Adhesive | Industrial-grade adhesive for metal surfaces |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Storage Temperature | -55°C to +100°C (-67°F to +212°F) |

| IP Rating | IP68 (dust-tight & waterproof) |

| Encoding Support | User-programmable, 96-bit EPC |

| Printability | Thermal transfer printable |

| Compatibility | Works with standard UHF RFID printers and readers |

Applications Across Industries

- Manufacturing & Industrial Plants – Track machinery, tools, metal crates, and parts

- Logistics & Warehousing – Identify reusable containers, racks, and trolleys

- IT Asset Management – Tag server racks, laptops, and other metal-based tech assets

- Utilities & Energy Sector – Label pipes, transformers, or metal infrastructure

- Construction & Field Equipment – Manage tools, vehicles, and safety gear in the field

Where high-performance tagging on metal matters, our UHF RFID on metal solution delivers.

Take control of your asset management—on metal, on your terms.

The Flexible UHF RFID on metal label is the smart, scalable choice for forward-thinking organizations. Whether you’re tagging equipment in a refinery or streamlining warehouse operations, this label adapts to your needs.

- Order today to bring superior RFID tracking to your metal assets.

Need bulk customization or integration support? Contact us now—our RFID experts are here to help!

FAQs – 25mm White RFID on Metal Label

Can I print barcodes or logos on this RFID on metal label?

Absolutely. The label is thermal-transfer printable for full customization, including barcodes, branding, and text.

Can this be used with any UHF RFID reader?

Yes. It’s compliant with EPCglobal Class 1 Gen2 and ISO 18000-6C, ensuring broad reader compatibility.

How is this different from a standard RFID label?

Standard RFID tags fail on metal. This UHF RFID on metal label is engineered specifically for metallic surfaces with shielding and tuned antennas.

How long does the RFID chip retain data?

The chip offers over 10 years of data retention and supports 100,000 write cycles.

What is the MOQ?

The MOQ for UHF RFID on metal labels is 100 pieces.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.

Looking for Custom RFID Tags?

Click here to share your specific requirements, and our team will promptly create a custom RFID tag solution for you.