High Temperature RFID Tags

High temperature RFID tags are engineered to withstand extreme environments and sustained high temperatures, ensuring reliable performance in a wide range of applications. Perfect for industries such as healthcare, automotive, and oil & gas, these durable tags provide accurate data even in harsh conditions.

Product categories

Ask Our Experts

High Temperature RFID Tags for Extreme Industrial Environments

Our high-temperature RFID tags leverage advanced RFID technology to reliably read meters across various frequencies, including 125 KHz, 13.56 MHz, and UHF 915 MHz. These tags are built to withstand harsh environments and are constructed with durable materials such as Nylon, Teflon, Ceramics, PCB, and proprietary high-temperature compounds. Standard heat-resistant RFID tags operate effectively between 200 °C and 230 °C, while our extreme and ultra-high temperature tags can endure temperatures up to 300 °C and 400 °C respectively. This makes them ideal for demanding applications in automotive manufacturing, downhill drilling, and high-heat manufacturing processes.

We offer a diverse range of high-temperature RFID tags to suit various needs, from embedded RFID wire tags to specialized RFID laundry tags. These versatile tags are perfect for tracking pallets, managing autoclaves, monitoring post-paint processes, and handling industrial laundry operations. Whether you need robust ceramic RFID tags or other high-temperature solutions, our selection ensures accurate and reliable data capture in even the most challenging conditions. Explore our high-temperature RFID tag offerings today to enhance operational efficiency and maintain precise tracking in high-heat environments.

Types of Heat-Resistant RFID Tags We Offer

We provide a wide range of industrial RFID tags designed for high-temperature use cases:

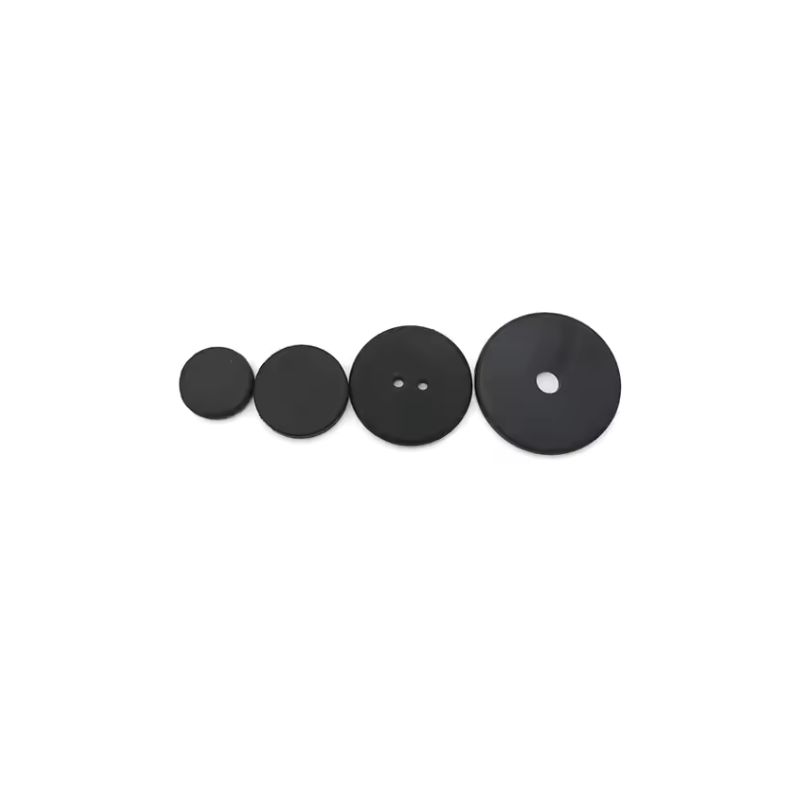

PPS Laundry RFID Tags

Made from PPS (polyphenylene sulfide), these tags are built to endure repeated exposure to high temperatures, water, and chemicals, making them perfect for industrial laundry and sterilization. These heat-resistant RFID tags are widely used in healthcare, uniforms, and textile management.

PEEK High Temperature RFID Tags

Constructed from PEEK (Polyether Ether Ketone), these high-performance tags offer exceptional heat resistance up to 260°C along with excellent chemical stability. Suitable for aerospace, automotive, chemical manufacturing, and other high-temperature industrial environments.

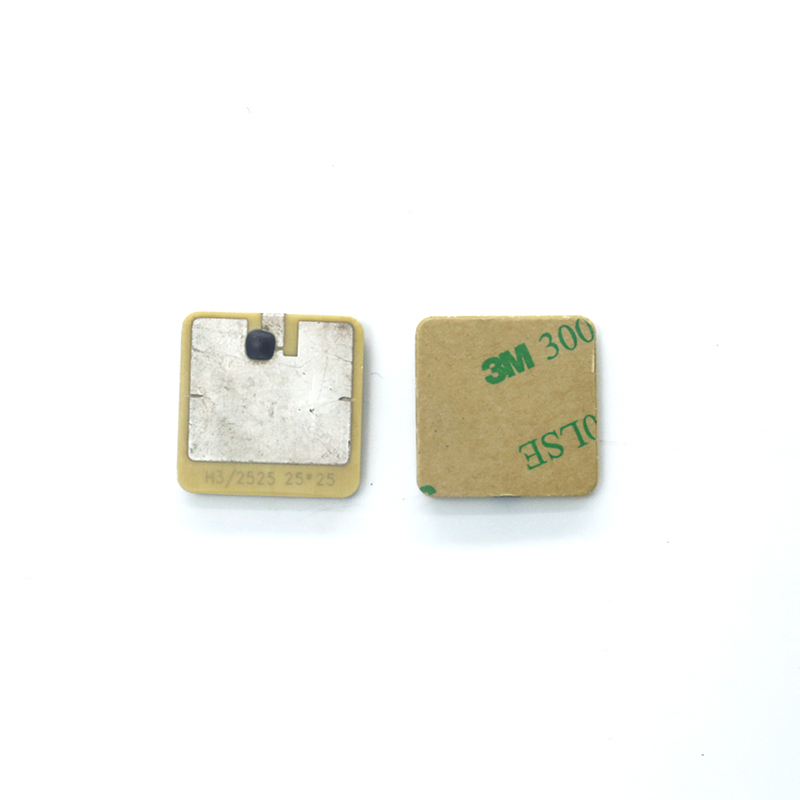

PCB RFID Tags

These PCB-based high temperature RFID tags offer excellent mechanical strength and are suitable for automation systems, electronics tracking, and industrial environments with sustained heat exposure. Available in passive and UHF formats, they deliver reliable read performance on or near metal.

Ceramic RFID Tags

Designed for extreme heat environments, ceramic RFID tags can endure temperatures above 250°C, making them ideal for metal processing, aerospace, and furnace tracking. Their robust structure also resists chemicals and physical wear.

Screw-Mount RFID Tags

We offer heat-resistant RFID tags with both industrial adhesive backing and screw or rivet mount designs for permanent installation. These tags are ideal for tagging equipment, trays, and containers exposed to high temperatures and rough handling.

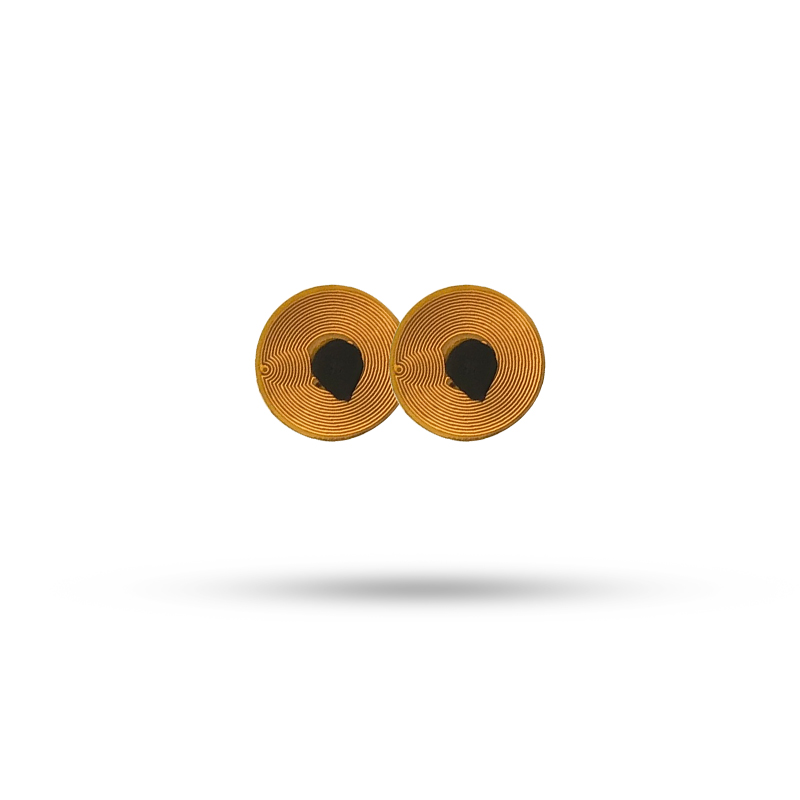

FPC RFID Tags

FPC (Flexible Printed Circuit) RFID tags offer a slim, flexible design that withstands moderate to high temperatures while remaining easy to install on curved surfaces.

Ideal for compact applications where space is limited and some thermal resistance is required.

Need Help Choosing the Right High Temperature RFID Tag?

Not sure which RFID tag suits your environment or industry? Contact our team today for expert support or to request a free consultation. Let us help you find or customize the perfect RFID tag for high-temperature tracking.

Features of Our High-Temperature RFID Tags

Extreme Heat Resistance

Operates reliably from 150°C up to 280°C depending on tag type.

UHF & Passive Options

Offers both long-range and battery-free functionality.

Durable Build

Resistant to moisture, dust, impact, and corrosive chemicals.

Metal-Friendly

Works directly on or near metal without signal loss.

Flexible Installation

Available in adhesive, rivet, or embedded mounting styles.

Customizable

Choose frequency, material, encoding, size, and logo printing.

Why Choose Us?

- Over 10+ years of experience in RFID technology manufacturing and customization.

- Proven in Industry – Trusted by automotive, oil & gas, healthcare, aerospace, and manufacturing companies.

- Fast prototyping and scalable production — MOQ as low as 100 pcs.

- Free consultation on material, frequency, and antenna design for your application.

- ISO-certified manufacturing and 100% quality-tested tags.

- Global shipping with an on-time delivery rate of 98%.

Trusted by brands worldwide, we combine engineering expertise with industry insight to deliver RFID solutions that work right — the first time.

Applications of High-Temperature RFID Tags

Our high-temperature RFID tags are trusted by industries worldwide:

Automotive Manufacturing

In automotive paint shops, high temp RFID tags survive ovens and curing processes where temperatures can exceed 200 °C. They are widely used for tracking car bodies, metal parts, and components throughout the production line, ensuring precise identification at every stage of the process. This reduces errors and improves production efficiency.

Oil & Gas Drilling

In oil and gas operations, high temperature UHF RFID tags are applied to drilling tools and downhole equipment that face extreme heat and pressure. These tags help operators monitor tool usage, manage drilling assets, and maintain safety compliance even in the harshest drilling conditions.

Industrial Laundry & Healthcare

Autoclave RFID tags are built to withstand repeated exposure to steam, sterilization, and high-pressure washing cycles. Hospitals use them for tracking surgical instruments and linens, while industrial laundries apply them for uniform and textile management, ensuring accountability and efficiency in large-scale operations.

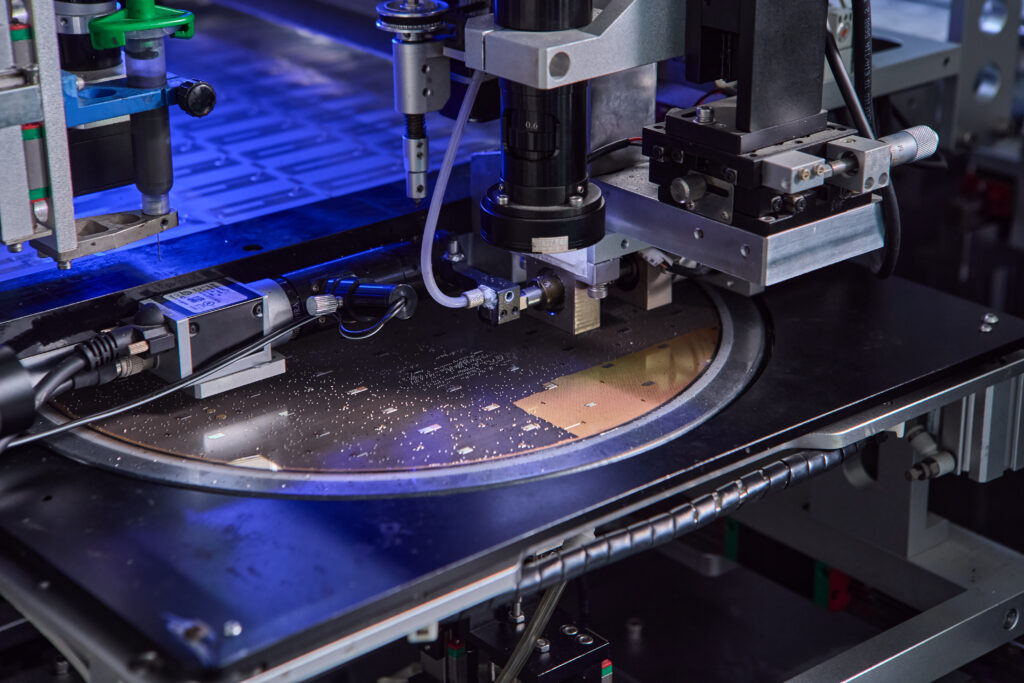

Metal Production & Foundries

In foundries and smelting plants, RFID tags high temperature resistant are attached to molds, pallets, and metal tools. These tags remain functional even near furnaces and casting processes, helping track equipment usage, manage assets, and improve process visibility in high-heat environments.

Aerospace & Defense

Aerospace and defense industries rely on industrial RFID tags for monitoring critical components exposed to extreme mechanical stress and heat. These tags enable accurate tracking of turbine parts, engine components, and high-value tools, ensuring safety, compliance, and reliability in mission-critical operations.

Frequently Asked Questions

What makes an RFID tag high temperature resistant?

High temp RFID tags are made from heat-tolerant materials like PPS or ceramic and use high-temp adhesives or casings to prevent signal loss or degradation in extreme heat.

What temperatures can your RFID tags withstand?

Depending on the tag type, our high temperature RFID tags can withstand temperatures from 150°C to 280°C continuously or even higher for short durations.

Are these tags suitable for metal surfaces?

Absolutely. Many of our RFID high temperature tags are designed to perform reliably on or near metal, even in harsh thermal environments.

What is the MOQ (Minimum Order Quantity)?

Our MOQ is flexible — we support small test orders and large production runs. Contact us with your project details, and we’ll recommend the best option.