Related Blog

How Does Radio Frequency Identification Work

This article explores the transformative power of Radio Frequency Identification (RFID) technology across various sectors.

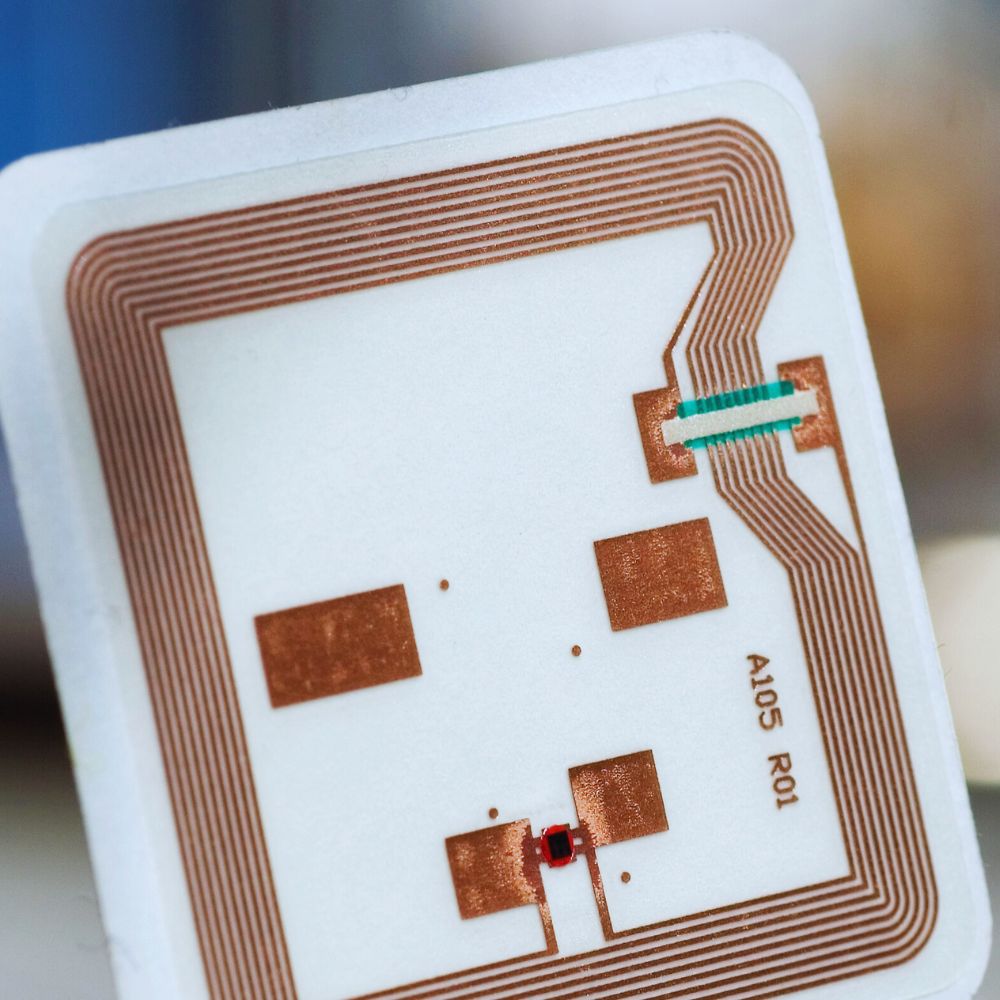

How Do RFID Tags Work

This article demystifies the inner workings of RFID technology, focusing on how RFID tags work to transform operations across diverse sectors.

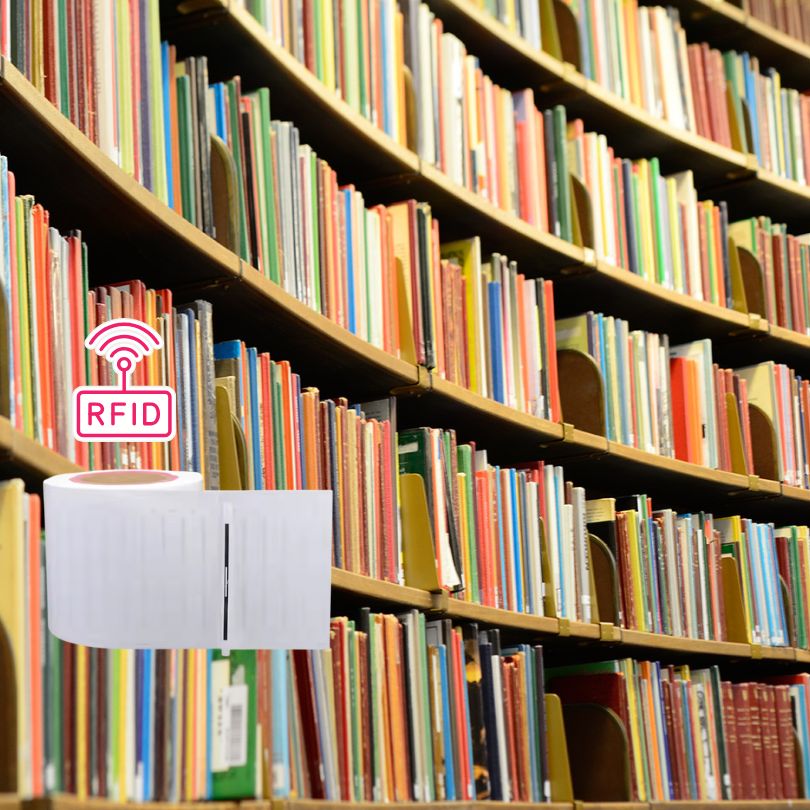

Can RFID Tags Track Location

RFID tags have become indispensable tools for businesses seeking to improve efficiency and visibility across various operations. While commonly known for inventory management and theft prevention, a frequent question arises: Can RFID tags be used for location tracking?