Sorodni blog

Kaj je NFC na mojem telefonu

Komunikacija bližnjega polja (NFC) spreminja našo interakcijo z našimi telefoni Android in svetom okoli nas, zlasti glede plačil.

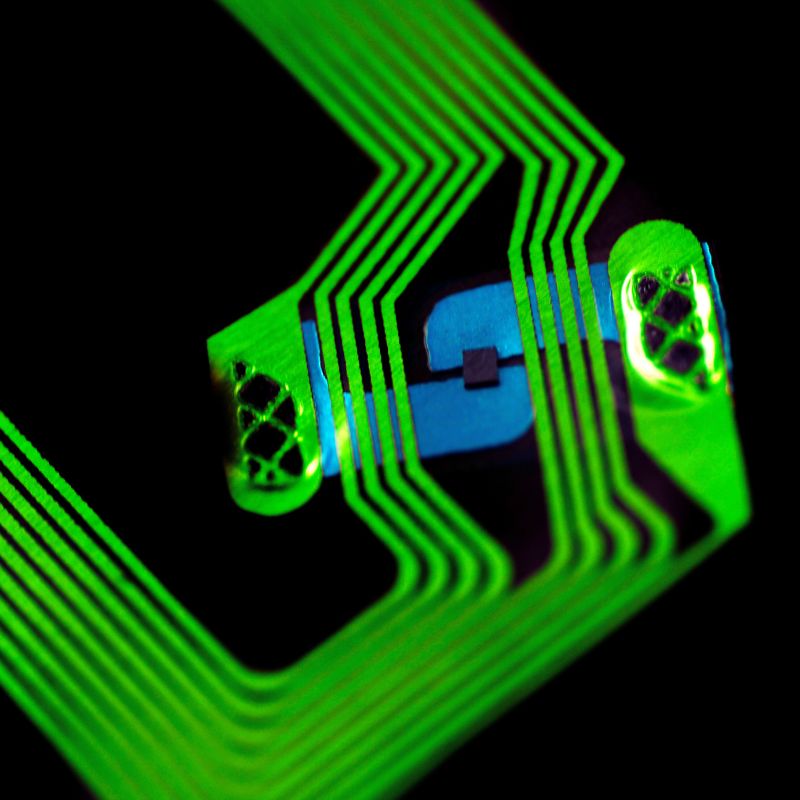

Kakšna je razlika med UHF RFID in HF RFID

Se sprašujete, kakšna je razlika med UHF RFID in HF RFID? Kot nekdo, ki je specializiran za razlago razlik med UHF RFID in HF RFID, sem delal na neštetih projektih, kjer bi lahko izbira prave frekvence povzročila ali prekinila uvedbo sistema RFID.

Ali Amazon v skladiščih uporablja tehnologijo RFID

Amazon, vodilni svetovni trgovec na drobno in v logistiki, je s tehnologijo RFID bistveno izboljšal delovanje skladišča. Tehnologija RFID (radiofrekvenčna identifikacija) poenostavlja upravljanje zalog, izboljšuje vidnost dobavne verige in zmanjšuje število napak v primerjavi s tradicionalnimi sistemi črtnih kod.