- Hjem

- Egendefinerte RFID-brikker

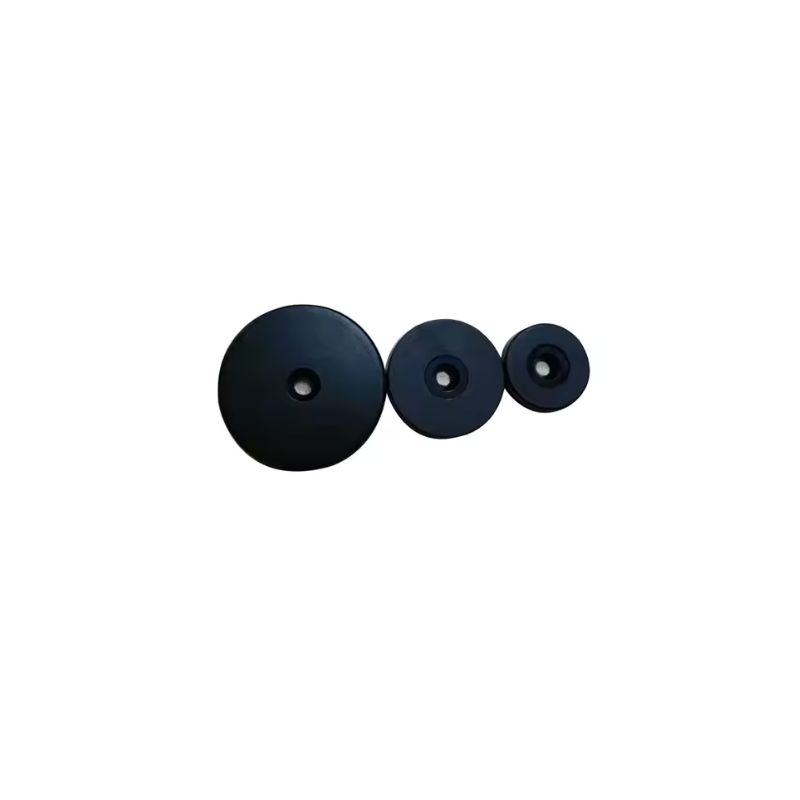

- Passiv RFID-tagg med lang rekkevidde Asset Tracking Anti-Metal Tag

Passiv RFID-tagg med lang rekkevidde Asset Tracking Anti-Metal Tag

Passiv RFID-brikke med lang rekkevidde for høye temperaturer og metallmiljøer

Spor eiendelene dine under de tøffeste industrielle forhold med våre passive RFID-brikker med lang rekkevidde. Disse RFID-brikkene er konstruert for å tåle høye temperaturer og metallinterferens, noe som gjør dem til det beste valget for bransjer som bilindustrien, romfart, produksjon og olje- og gassindustrien.

Enten du håndterer deler i en lakkboks eller utstyr i en ovn, kan du bruke vår anti-metall, RFID-brikker med høy temperatur gir lang rekkevidde og robust ytelse.

Hvorfor velge våre passive RFID-brikker for tøffe miljøer?

Tradisjonelle tagger svikter der våre utmerker seg. Våre passive RFID-brikker med lang rekkevidde er spesielt utviklet for:

- Pålitelig skanning med lang rekkevidde på opptil 8 meter.

- Høy temperaturbestandighet opp til 200 °C

- Antimetallisk ytelse ved montering på metalliske overflater

- Batterifri passiv drift for lite vedlikehold og lang levetid

- Kjemikalieresistens mot oljer, syrer og løsemidler

Disse brikkene sikrer uavbrutt sporing av eiendeler selv i de tøffeste industrielle omgivelser.

Viktige egenskaper ved våre passive RFID-brikker med lang rekkevidde

- Ekstrem varmebestandighet - tåler opp til 200 °C+

- Lang rekkevidde - opptil 8 meter, avhengig av omgivelsene

- Anti-metallisk design - fungerer på metalliske eiendeler

- Passiv UHF-teknologi - ingen batterier kreves

- Tilpassbare størrelser og montering - tilgjengelig i keramikk, PPS, teflon

- Slitesterk og vanntett (IP68) - motstandsdyktig mot kjemikalier og tøft vær

- Fleksibel montering - skrue, lim, sveising eller tilpassede oppsett

Bruksområder for passive RFID-brikker med høy temperatur

Våre robuste RFID-brikker er pålitelige i bransjer som krever holdbarhet og presisjon:

- Bilproduksjon - Spor deler gjennom lakkering og varmebehandling

- Luft- og romfart - Overvåk komponenter under drift ved høye temperaturer

- Olje og gass - Merking av utstyr under ekstreme utendørsforhold

- Industrielle verktøy og maskiner - Sanntidssporing i produksjonslinjer

- Helsetjenester - Steriliser og gjenbruk RFID-merket medisinsk utstyr

- Logistikk og sporing av eiendeler - Oppretthold synlighet i komplekse forsyningskjeder

Tekniske spesifikasjoner

| Trekk | Spesifikasjon |

| RFID-protokoll | EPC Klasse 1 Gen 2 / ISO 18000-6C |

| Hyppighet | 860-960 MHz (UHF) |

| Chip Type | Impinj Monza 4QT, NXP UCODE G2iM |

| Les Range | Opp til 8 meter |

| EPC-minne | 96-bit til 512-bit |

| Brukerminne | Opp til 2048 bits |

| Driftstemp | '-40 °C til +200 °C |

| Overlevelsestemperatur | 'Opp til +220 °C |

| Materialalternativer | Keramikk, PPS, teflon |

| IP-vurdering | IP68 eller høyere |

| Montering | Skrue, selvklebende, sveisbar |

| Størrelser | 10 mm-50 mm (kan tilpasses) |

| Kjemisk motstand | Syrer, løsemidler, oljer |

Skaff deg tilpassede RFID-tagger

Som en ledende spesialtilpasset RFID-brikkeprodusent, lager vi løsninger basert på de unike behovene til din virksomhet. Vi tilbyr et bredt spekter av tilpasningsalternativer, inkludert materiale, størrelse, frekvens, koding og leseavstand, for å sikre at hver RFID-tag er perfekt tilpasset dine behov. Uansett hvilken applikasjon du bruker RFID-brikker til, kan vi tilby robuste, pålitelige RFID-brikker som oppfyller de høyeste kvalitets- og holdbarhetsstandardene. Her er de viktigste måtene vi tilpasser RFID-brikker for å passe dine behov.

Materialvalg

Materiale er nøkkelen for å tilpasse RFID-brikker. Plast fungerer under tøffe forhold, mens mykere materialer passer til sarte rom. Ulike materialer påvirker også signalytelsen. Velg det som passer din brukssituasjon for å sikre at taggene dine varer og fungerer pålitelig.

Tilpasset størrelse

Størrelsen former brukervennligheten. Små etiketter passer til trange steder eller små gjenstander, mens større etiketter er lett å lese. I overfylte områder forhindrer elegante etiketter sammenstøt. Juster form og dimensjon med varene dine for synlighet, bekvemmelighet og ytelse.

Frekvenskrav

Velg LF, HF eller UHF basert på leseområde, hastighet og interferens. LF og HF motstår metaller og væsker, men har kortere rekkevidde. UHF tilbyr en utvidet rekkevidde, men kan møte signalblokker. Tilpass frekvensen til ditt miljø for pålitelig ytelse.

Leseavstand

Definer avstanden du må lese taggen på. Korte avstander fungerer for butikkkasser, mens varehus kan trenge metervis med dekning. Antennedesign, leserinnstillinger og strømutganger påvirker rekkevidden. Juster disse faktorene for å fange data nøyaktig på den avstanden du trenger.

Kode

Planlegg hvordan data lagres på hver tag. Noen har bare en ID, mens andre inneholder detaljert informasjon. Bestem om du trenger en enkel EPC eller ekstra brukerminne. Sørg for at det valgte formatet fungerer med eksisterende programvare. Riktig koding effektiviserer prosesser og reduserer feil.

Applikasjonsmiljø

Vurder virkelige forhold. Temperatursvingninger, fuktighet og kjemikalier kan forringe merker. For utendørs bruk, velg UV-bestandige foringsrør. Sørg for overholdelse av sikkerhetsreglene i helsevesenet eller matmiljøer. Å matche taggene dine til miljøet maksimerer levetiden deres.

Relaterte produkter

Tilpass eventuelle RFID-brikker fra fabrikken vår for å møte dine krav.