Om oss

Vi er den ledende produsenten av høykvalitets cutom RFID-brikker, for å gjøre ting smartere og enklere.

Om selskapet vårt

Hvem er vi?

Vi er en ledende høyteknologisk leverandør som spesialiserer seg på RFID-brikker. Ved å utnytte avansert teknologi og et team av erfarne fagfolk, leverer vi presise, kostnadseffektive løsninger som møter våre kunders ulike behov. Vårt engasjerte personale gir omfattende støtte for alle aspekter av våre produkter og tjenester. Vi tror på å fremme langsiktige partnerskap bygget på gjensidig suksess, kontinuerlig forbedring og delt vekst.

Hva gjør vi?

Vi bruker vår omfattende industrielle design- og produksjonsekspertise til å lage et bredt spekter av pålitelige RFID-brikker med høy ytelse. Vårt produktspekter inkluderer RFID-klistremerker og -etiketter, NFC-merker, RFID-merker på metall, høytemperatur-RFID-merker, RFID-forseglingsmerker, RFID-vaskemerker, RFID-merker for sporing av eiendeler og RFID-merker for inventar og husdyrhåndtering. Disse løsningene er mye brukt i vann og elektrisitet, medisinsk behandling, klesvask, sikkerhet, logistikk, lager, nye detaljhandel og industri 4.0-applikasjoner.

Hvordan gjør vi det?

Våre erfarne salgs-, tekniske support- og ettersalgseksperter er ekspertproblemløsere med dyp produktekspertise. De forstår grundig hvordan våre tilpassede RFID-brikker produseres, distribueres og vedlikeholdes og miljøene der de fungerer best. Salgsteamet vårt vil anbefale de best egnede produktene basert på din applikasjon, med tanke på materialer, dimensjoner, form, kostnader og ytelsesegenskaper. I tillegg gir vårt tekniske team ekspertveiledning og analyserer applikasjonsmiljøet ditt for å sikre at de valgte RFID-taggene leverer stabil, pålitelig ytelse.

Fabrikkområde

FoU-ingeniører

Arbeidere

Daglig produksjon

Produksjonsprosess

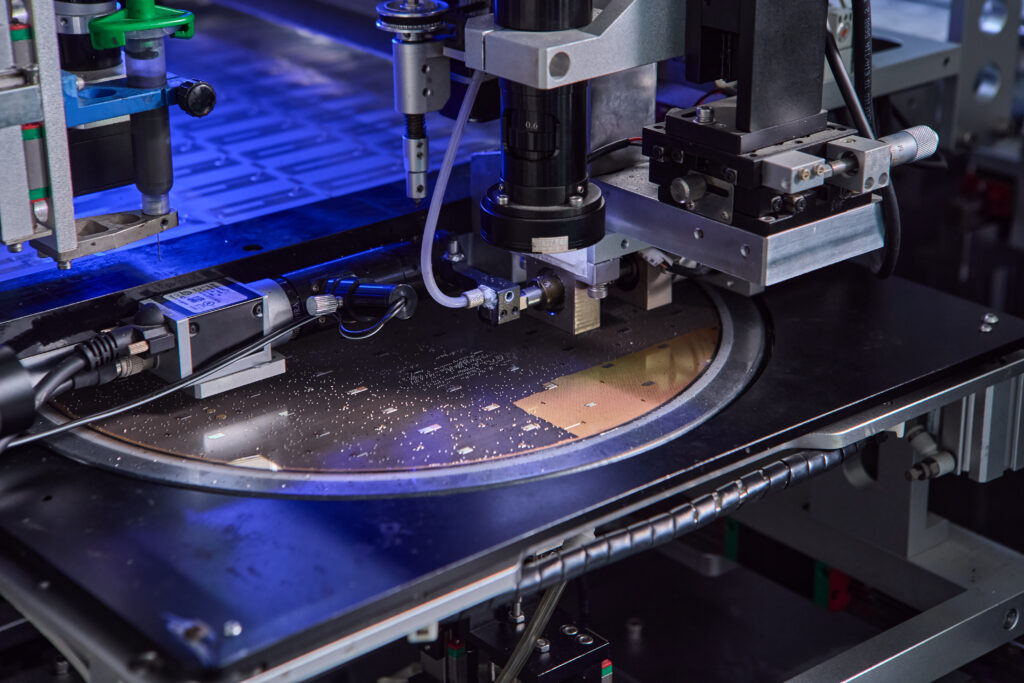

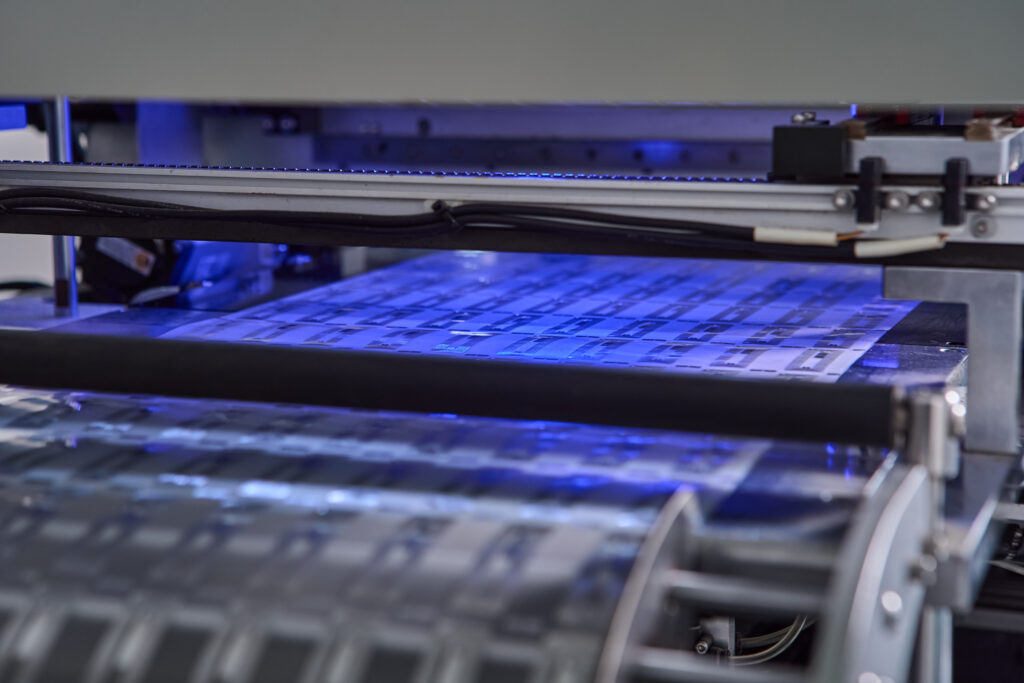

Flip-chip-innkapsling er et viktig trinn i RFID-produksjon. I denne prosessen blir RFID-brikken direkte loddet på et underlag med en antenne og deretter innkapslet i et beskyttende plastskall. Denne teknikken gir høyere integrasjon og bedre ytelse, og sikrer stabil drift av RFID-brikker under ulike forhold. Flip-chip-innkapslingsprosessen kan også forbedre produksjonseffektiviteten og redusere produksjonskostnadene, noe som gjør RFID-enheter mer praktiske og økonomiske.

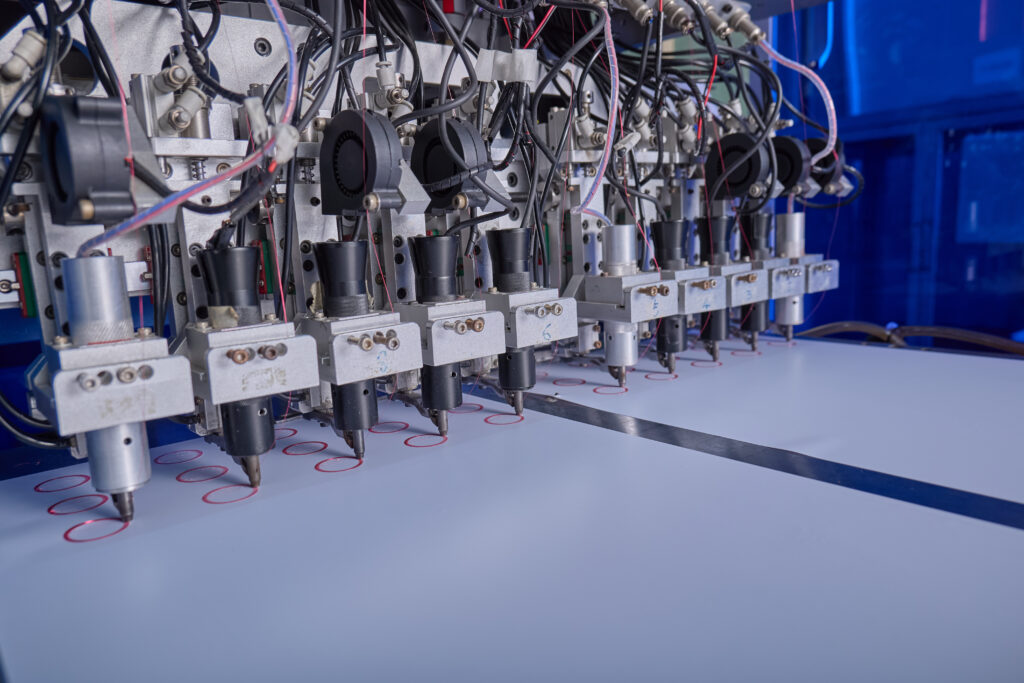

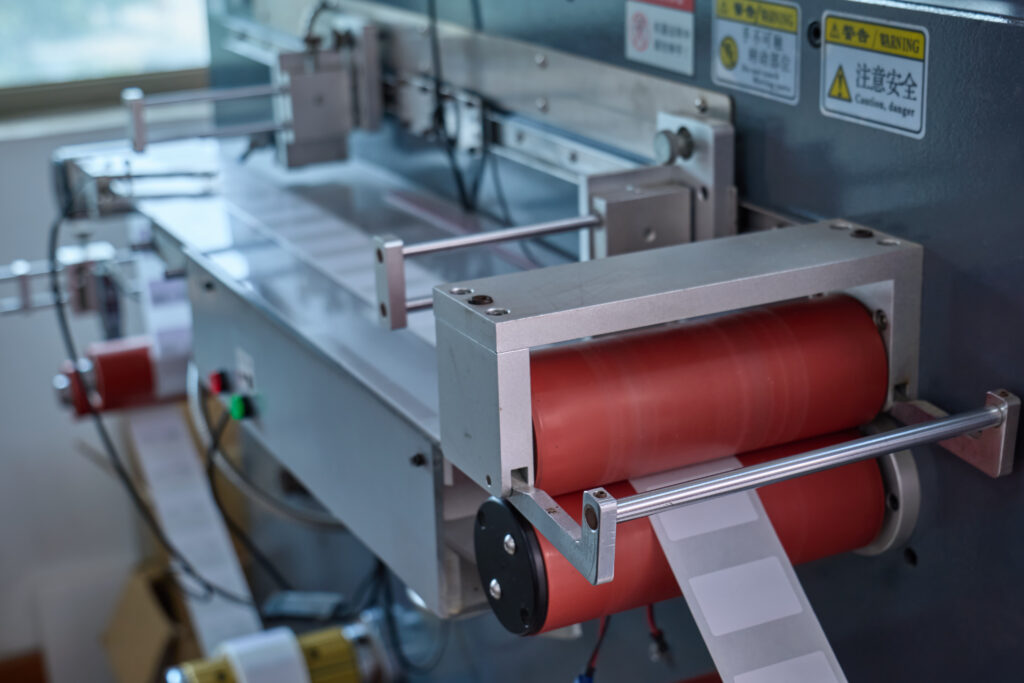

Stick Chip-prosessen er en viktig komponent i vår produksjonskjede. Denne fasen involverer nøyaktig plassering og binding av RFID-brikken til antennesubstratet, og sikrer optimal signaloverføring. Våre dyktige teknikere bruker avansert maskineri for å oppnå dette med bemerkelsesverdig nøyaktighet. Hver brikke gjennomgår strenge tester for kvalitetssikring, og oppfyller de høye standardene for bulkkjøpere og -distributører. "Stick Chip"-prosessen er et bevis på vår forpliktelse til overlegen kvalitet og ytelse i våre RFID-produkter. Opplev forskjellen i konsistens og pålitelighet med våre omhyggelig utformede RFID-løsninger, hvor presisjon og kvalitet er avgjørende.

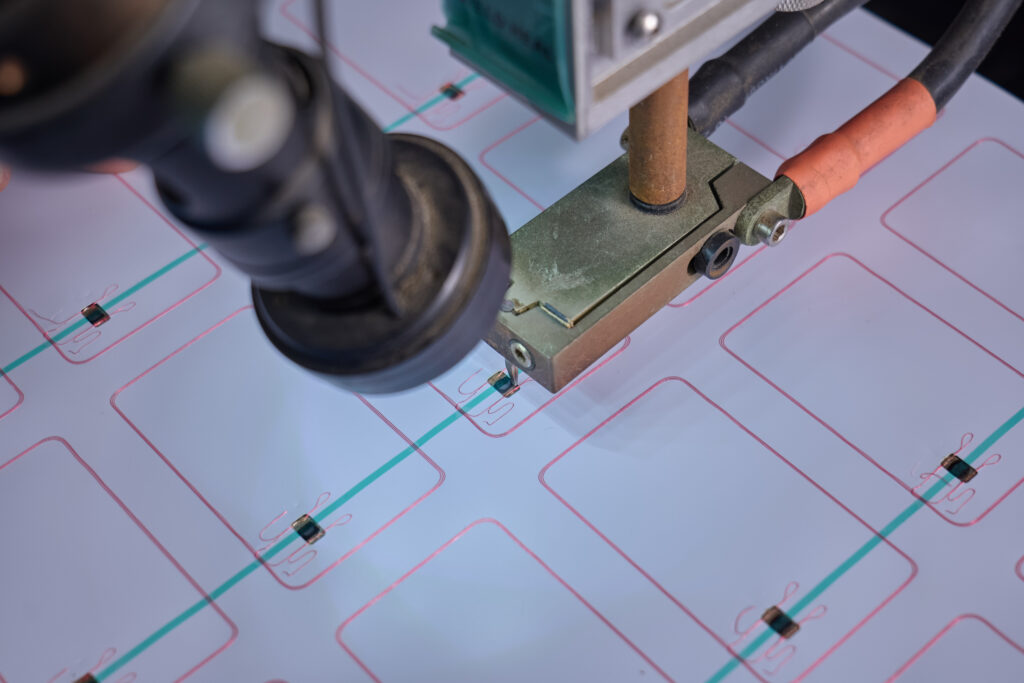

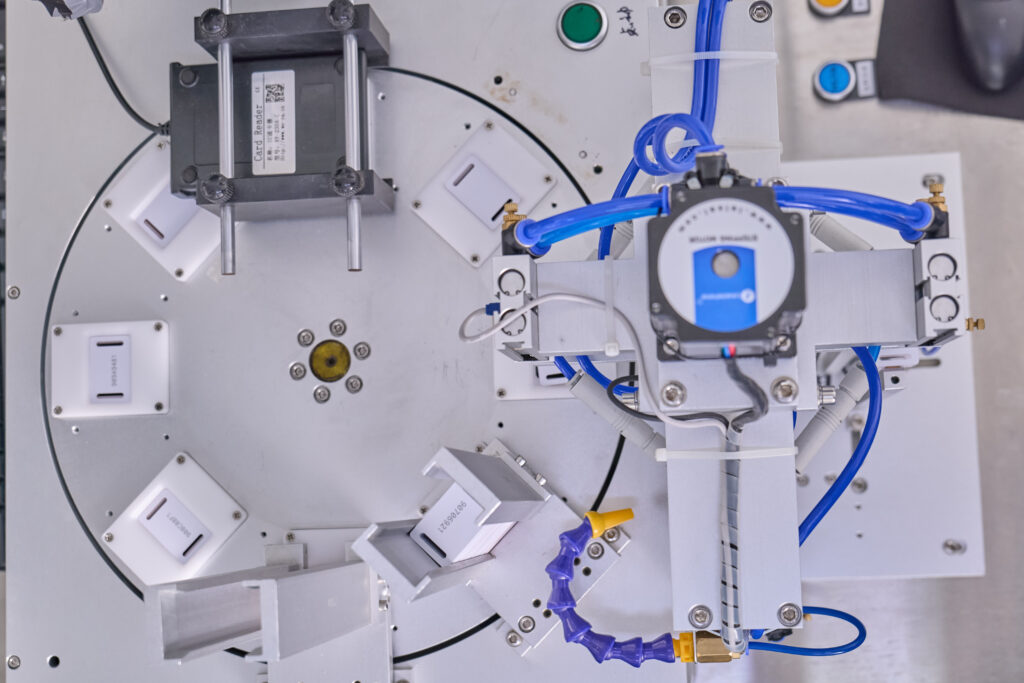

Automatisk sveiseprosess: Denne automatiserte prosessen sikrer optimale elektriske forbindelser mellom antennen og brikken, et avgjørende trinn i RFID-brikkeproduksjon. Våre strenge kvalitetskontrolltiltak implementeres i hvert trinn, for å sikre at hver sveis er perfekt, og at produktene våre er av høyeste kvalitet. Vi bruker avansert teknologi og dyktige teknikere for å overvåke denne prosessen, og garanterer konsistens og pålitelighet for våre bulkkjøpere og distributører. Vår forpliktelse til fortreffelighet i vår autosveiseprosess skiller oss ut i RFID-industrien.

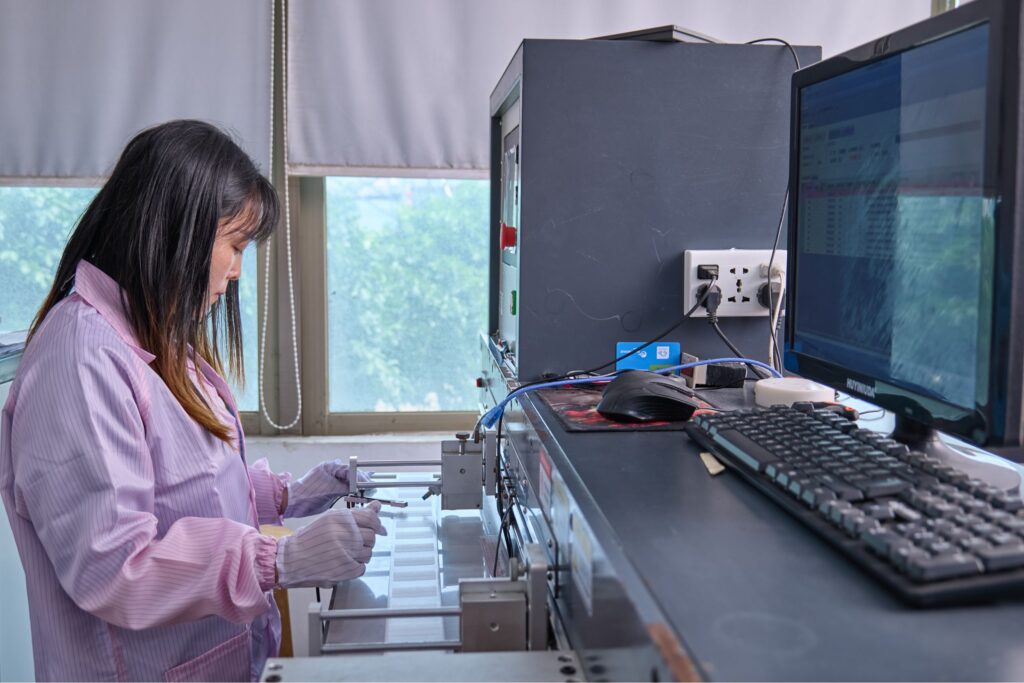

Vi tror at "Testing" er en hjørnestein i produksjonsprosessen vår. Hver RFID-brikke gjennomgår strenge tester for å sikre overlegen ytelse og holdbarhet. Våre omfattende testprosedyrer inkluderer funksjonalitetskontroller, frekvenstesting og stresstester under ulike miljøforhold. Vi bruker avansert testutstyr og metoder for å sikre at hvert produkt oppfyller våre strenge kvalitetsstandarder. Våre erfarne teknikere overvåker denne prosessen nøye, og sikrer jevn kvalitet og pålitelighet for våre bulkkjøpere og distributører. Denne grundige oppmerksomheten på detaljer i testfasen vår understreker vår forpliktelse til å levere høykvalitets RFID-produkter til industrien.

Kombinasjonen er et kritisk skritt som sikrer våre produkters høye kvalitet og pålitelighet. Dette stadiet involverer den nøyaktige monteringen av antennen og brikken, hvor hver komponent er nøye kombinert for å danne den integrerte strukturen til RFID-brikkene. Våre erfarne teknikere bruker toppmoderne utstyr for å garantere disse delenes nøyaktige justering og sikre feste. Denne strenge prosessen overvåkes nøye og blir utsatt for strenge kvalitetskontroller, for å sikre at hvert produkt vi produserer oppfyller de høyeste ytelses- og holdbarhetsstandardene. Vår forpliktelse til fortreffelighet i denne avgjørende produksjonsfasen skiller oss ut, noe som gjør oss til det beste valget for bulkkjøpere og distributører som søker førsteklasses RFID-løsninger.

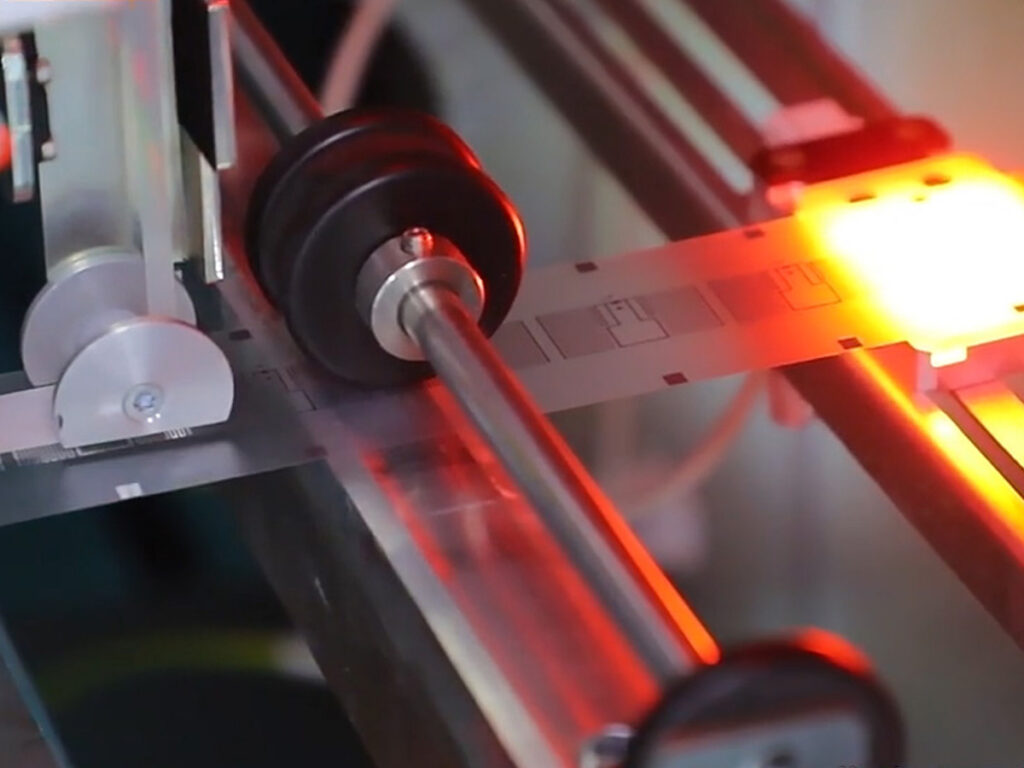

Innleggslamineringsfasen er sentral for å sikre holdbarheten og levetiden til RFID-brikkene våre. Under Inlay Lamination er det sammensatte RFID-innlegget innkapslet mellom lag av slitesterkt materiale, noe som gir beskyttelse og forbedrer produktets generelle stabilitet. Våre avanserte lamineringsteknikker og utstyr sikrer en sømløs, sikker innkapsling, og bevarer de integrerte komponentene fra miljøfaktorer. Det utføres strenge kvalitetskontroller gjennom denne prosessen, og opprettholder vår forpliktelse til å levere robuste RFID-løsninger av høy kvalitet. Denne dedikasjonen til fortreffelighet i vår produksjonsprosess er grunnen til at bulkkjøpere og -distributører overlater RFID-kravene til oss.

Kvalitetskontroll for tilpassede RFID-brikker

Overholdelse av strenge kvalitetsstyringstrinn og bransjestandarder sikrer at hver RFID-tag oppfyller strenge ytelses- og pålitelighetsstandarder, noe som til slutt øker produktiviteten og kundetilfredsheten.

Prosessovervåking

Under produksjon må prosessparametere (som pletteringstid, strøm, temperatur osv.) kontrolleres kontinuerlig for å sikre at de er innenfor kontrollgrensene. Dette kan gjøres gjennom ulike teknikker for statistisk prosesskontroll (SPC). Hvert trinn er et viktig kvalitetskontrolltrinn i RFID-brikkeproduksjon og krever grundig og streng håndtering og inspeksjon.

Mellomproduktinspeksjon

Vår mellomproduktinspeksjon sikrer høyeste kvalitet i RFID-produksjon. Vi undersøker nøye hvert produkt i ulike produksjonsstadier, og bekrefter dets funksjonalitet og overholdelse av designspesifikasjoner. Vår strenge inspeksjonsprosess ivaretar merkevarepålitelighet og kundetilfredshet, noe som gjør oss til det pålitelige valget for selgere og distributører over hele verden.

Sluttprodukttesting

På vår RFID-fabrikk er testing av sluttprodukter et avgjørende trinn i vår kvalitetskontrollprosess. Hvert produkt gjennomgår en omfattende, trinn-for-trinn-evaluering. Det begynner med fysisk inspeksjon for designnøyaktighet, etterfulgt av funksjonell testing for å sikre optimal ytelse. Deretter utfører vi holdbarhetstester under ulike forhold for å bekrefte motstandskraft. Til slutt utfører vi en grundig skanning for å verifisere integriteten til RFID-dataene. Denne grundige prosessen garanterer at produktene våre oppfyller de høye standardene som forventes av merkevarehandlere og -distributører.

Defekt produkttilbakemelding og forbedring

Våre defekte produkttilbakemeldinger og forbedringsprosesser er strenge, noe som sikrer at hvert produkt oppfyller de høyeste standardene. Ved identifisering av et defekt produkt, blir det umiddelbart isolert og analysert. Grunnårsaken er identifisert, etterfulgt av en omfattende gjennomgang av produksjonsprosessen. Nødvendige forbedringer blir deretter implementert, med endringer grundig testet. Denne grundige, steg-for-steg-tilnærmingen garanterer konsekvent levering av høykvalitets RFID-brikker til våre verdsatte kunder.