Long Range UHF Metal Mount RFID Tags for Logistics

High-Performance UHF Metal Mount RFID Tags for Logistics and Industrial Applications

Excellent Performance in Metal Asset Tracking for Logistics and Industry

Our Long Range UHF Metal Mount RFID Tags, are engineered to provide unparalleled performance when attached to metal objects in logistics and other industrial applications. These specialized RFID tags are designed to excel where traditional RFID tags fall short, offering reliable and accurate tracking of metal assets such as computers, IT equipment, tools, machinery, and returnable containers. The metal-mount design includes an offset from the surface of the tagged item, ensuring that the tags function optimally despite the challenges posed by metal surfaces.

Designed for Reliable Asset Tracking and Versatile Industrial Applications

Our On-Metal RFID Tags are an essential tool for industries that rely on precise asset tracking and inventory management. Unlike standard RFID tags, which often suffer from interference when placed on metal, these tags are specifically tuned to overcome such obstacles. Available in various form factors and encapsulated for durability, they are suitable for a wide range of applications, including manufacturing, logistics, and heavy industry. The customization options available make them versatile for different operational needs.

Durable and High-Performance RFID Metal Tags for Challenging Environments

The RFID Metal Tags we offer are crafted with durability and performance in mind. Designed to withstand outdoor and harsh industrial environments, these tags ensure long-range readability and high accuracy, even in challenging conditions. They are particularly effective for metallic asset tracking, whether in oil and gas, mining, or warehouse management. Their robust construction and reliable performance make them an ideal choice for any industry where metal asset management is critical.

Improve Logistics Efficiency through Seamless Integration and Accurate Asset Tracking

Incorporating our Long Range UHF Metal Mount RFID Tags into your logistics operations streamlines asset tracking, enhances inventory accuracy, and ensures seamless integration with existing systems. These tags are not only a solution to the traditional challenges of metal interference but also an upgrade to your current asset management processes, providing the reliability and longevity required in demanding environments.

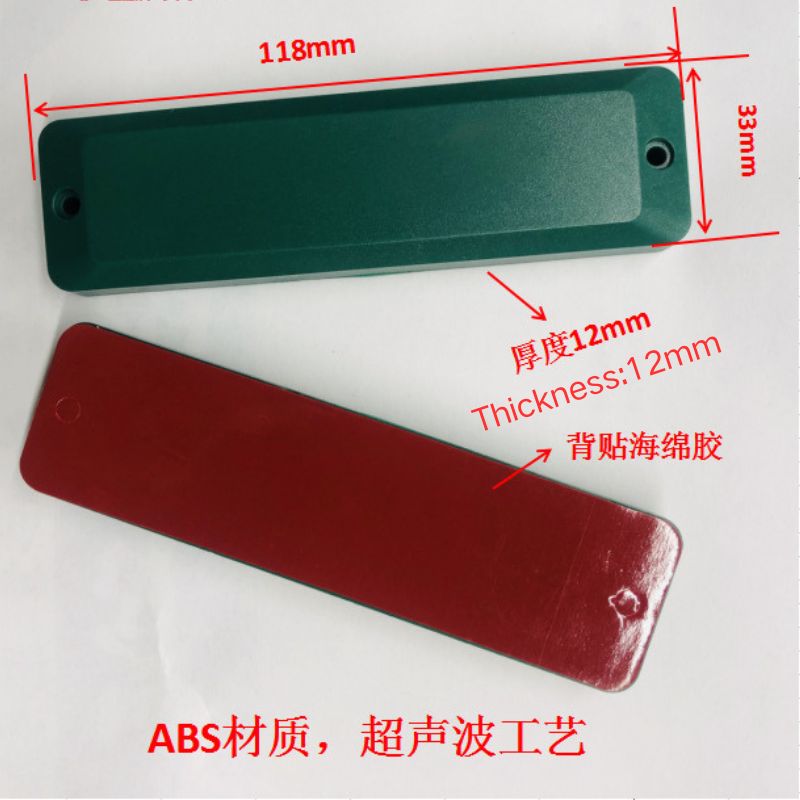

Metal Mount RFID Tags Technical Specification:

Material: ABS

Chip: R6A

Size: 118*33mm

Thickness: 12.2mm,

Color: White, Green.

Frequency: 860~960MHz

Protocol: ISO18000-6C

Customized: Logo printing, Serial number, and Barcode

Frequently Asked Question

The top questions about radio frequency identification, RFID tags, and RFID readers, and RFID cards.

RFID stands for Radio-Frequency Identification, a technology used for identifying people, animals, or objects using radio-frequency communication. This identification is facilitated by RFID tags, or transponders, each equipped with a unique identification number and, in some cases, additional memory.

Passive RFID tags are particularly cost-effective, priced at around €0.05, and do not require an external power source. This affordability and ease of use make them ideal for a wide array of applications, including logistics, inventory management, supply chain operations, automation, marketing, and many other fields.

An RFID tag is a chip or transponder equipped with an antenna that amplifies radio signals. Typically, an RFID tag resembles a label with a visible circuit. When adhesive, it is known as a “wet inlay,” and when non-adhesive, it is called a “dry inlay.”

Active Tags

Active tags come with an internal battery, which is typically used to boost transmission power and extend the reading distance. A common example of active tags is the Bluetooth Beacon.

Passive Tags

Passive tags lack an internal power source and instead use a capacitor. Once charged, this capacitor generates an electromagnetic field that transmits the information stored in the chip. An RFID reader powers and reads the tag in a fraction of a second. Passive tags are the most common type because they do not require a battery.

For a complete overview, there are also semi-active tags. These tags have a power supply that is not used for radio circuits but rather for additional features such as temperature or motion sensors.

RFID tags are read or detected using specialized fixed or mobile devices known as RFID readers. These readers activate the transponder through induction or electromagnetism, prompting it to transmit the stored information. RFID readers can come with either an integrated or an external antenna. Some models allow multiple antennas to be connected to a single reader, enabling the identification of tags at various locations or providing precise coverage of a specific area.

RFID technology operates at various frequencies, each with unique characteristics and governed by ISO standards. Here are the most common RFID frequency categories:

125/134 kHz – RFID LF (Low Frequencies): Governed by the ISO 18000-2 standard, these low-frequency tags have a reading distance of a few centimeters and a low data transmission speed. They are primarily used for animal identification, vending machines, burglar alarms, and access control.

13.56 MHz – RFID HF (High Frequencies): Governed by the ISO 18000-3 standard, these high-frequency tags have a reading distance of up to 10 centimeters and a low to medium data transmission speed. This frequency is also known as NFC (Near Field Communication) and is increasingly popular because many smartphones can act as readers, enabling various innovative applications.

860-960 MHz – RFID UHF (Ultra High Frequencies): Governed by the ISO 18000-6 standard, UHF tags have a reading distance of several meters, even with passive tags. There are variations between UHF readers using US and European standards, but the RAIN standard ensures compatibility with both. UHF tags are widely used for logistics, inventory management, timekeeping, and access control.

5.8 GHz – RFID SHF (Super High Frequencies): Governed by the ISO 18000-5 standard, this is the highest RFID frequency range. It includes only active tags with internal batteries, allowing detection distances of hundreds of meters. A common example of SHF tags is those used for electronic toll collection (ETC).

Low-frequency (LF) readers are typically designed to read one tag at a time, such as the ID of a single livestock ear tag. In contrast, high-frequency (HF) and especially ultra-high frequency (UHF) readers are capable of reading multiple RFID tags simultaneously. This allows them to efficiently scan a stack of tagged books or a pallet of goods as they pass through a reader gate.

The most affordable RFID tags can cost just a few cents and are typically designed as adhesive labels. These low-cost tags are often used in retail or logistics for single-use applications in non-durable settings. The price of RFID tags can vary based on factors such as the chip’s capabilities, memory size, and durability against conditions like heat, impact, freezing, sunlight, and chemicals. Costs can range up to several dollars depending on these factors. Additionally, active tags, which include a battery, are generally more expensive than passive tags.

RFID tags generally store data in a variety of formats, depending on the tag’s capabilities. Some tags offer advanced features like file systems or designated memory areas for standardized data. While many proprietary formats are available, there are also standardized formats designed to ensure compatibility and interoperability between RFID tags, readers, and applications from different manufacturers.

RFID tags are available in a range of form factors to suit different applications, mounting methods, and durability needs. Typical form factors include:

- Sticky Label or Dry Inlay: Adhesive-backed tags for easy attachment.

- Glass Capsule: Encased in a glass vial, often used for animal tracking.

- Disc: Coin-shaped tags, sometimes with a central hole.

- Rectangular Block: Often equipped with screw holes or steel rings for secure mounting.

- ISO Card: Card-shaped tags similar to standard ID cards.

- Special Form Factors: Custom designs such as tags with built-in cable ties, tamper-evident features, or key fobs.

RFID tags offer several advantages over alternative technologies such as barcodes or QR codes. Key benefits include:

- No Line of Sight Required: RFID tags can be read even when embedded or dirty, unlike barcodes which require a clear view.

- Read/Write Capability: RFID tags support both reading and writing of data, unlike read-only technologies.

- Large Memory Capacity: Tags can store substantial amounts of data, up to 32KB.

- Enhanced Security: Options for cryptographic or password-based security are available.

- Long Reading Range: UHF RFID tags can be read from several meters or feet away.

- Simultaneous Tag Reading: Multiple tags can be read at once, such as scanning an entire pallet of goods.

The reading distance of RFID tags varies based on several factors, including:

- Antenna Size: The size of the tag’s antenna affects its range.

- Tag Chip: The type of chip used in the tag can influence the distance.

- Tag Orientation: How the tag is positioned within the reader’s field impacts its readability.

- Reader Field Strength: The power of the RFID reader affects the range.

- Environmental Factors: Materials like metal or water around the tag can interfere with the signal.

Typically:

- LF, HF, and UHF Near-Field Tags: These tags generally have a reading range of about 1 foot (30 cm).

- UHF Far-Field Tags: These tags can be read from several meters or feet away, though performance can be significantly affected by environmental conditions.

- NFC Tags (HF): Designed for close-range communication, NFC tags usually have a reading distance of approximately 1 inch (2 cm) when used with smartphones or similar devices.

RFID tags are commonly used to uniquely identify physical items to which they are attached or embedded. Their applications are diverse, covering a wide range of physical objects. Key benefits of RFID tag use include:

- Enhanced Inventory Management: Increases speed and accuracy in tracking inventory.

- Reduction of Human Error: Minimizes mistakes associated with manual data entry.

- Streamlined Logistics: Optimizes the handling and workflow of items in the supply chain.

- Contactless Payment: Facilitates secure and convenient payment transactions.

- Access Control: Manages and controls access to secure areas or systems.

RFID tags are utilized whenever there is a need for quick and reliable identification of physical objects. Their applications are broad and continually expanding. Key areas where RFID tags are commonly used include:

- Animal Identification: For pets, livestock, and lab animals.

- Access Control Systems: For secure and contactless entry.

- Payments: For secure and convenient contactless transactions.

- Electronic Passports and ID Cards: For enhanced security and identification.

- Retail Logistics: To improve inventory management and tracking.

- Automation and Manufacturing: For efficient production and process control.

- Returnable Transport Items: To manage and track reusable containers.

- Commercial Laundry: For tracking and managing laundry items.

- Medical and Health Equipment: For managing medical devices and patient tracking.

- Waste Management: To track and manage waste disposal processes.

While passive RFID tags are generally maintenance-free and durable, several issues can affect their performance:

Readability at Distance: Tags may experience reduced readability at longer distances. Environmental factors, such as the presence of metal or water near the tag, can also interfere with reading. For guidance on mounting RFID tags effectively, refer to the white paper on Adhesive Tag Fixation.

Metal Interference: RFID tags often face reduced performance when placed near metal. Tags positioned directly on metal surfaces may not read at all. Special RFID tags designed for metal environments feature housing that creates a controlled gap between the tag antenna and the metal, or include metal foil to enhance performance near metal surfaces.

Proximity Issues: When RFID tags are placed too close to each other, they can interfere with one another, especially with UHF tags. Adhering to minimum spacing guidelines for each tag type is crucial for optimal performance.

Water and Moisture Impact: While most RFID tags are physically resistant to water, moisture can significantly reduce their read range. High-frequency (HF) and ultra-high-frequency (UHF) tags are particularly affected by moisture, with UHF tags showing a marked decrease in read range when wet. Low-frequency (LF) tags generally perform better in the presence of water.

Tag Fixation: Proper attachment of RFID tags to surfaces is essential. Choosing the right fixation method and ensuring maximum contact between the tag and the surface will help maintain the tag’s position, especially under mechanical shock and vibration. For adhesive tags, ensuring full contact is critical to prevent issues related to tag displacement.

Hot To Customize RFID Tags

Know the customization process about RFID tags

Size & Shape

Send your requirements on size and shapes. Tags are typically designed in simple shapes and sizes to match the internal antenna. However, they can also be customized in various sizes and shapes to best fit the intended application and the asset being tagged. For instance, RFID hang tags can be customized in size, shape, and attachment method to perfectly suit specific applications.

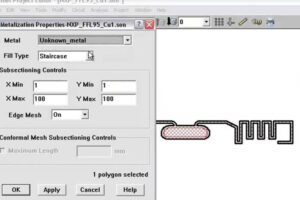

Layout & Chips

In the label format designer, select the layout that matches the type and size of the RFID label you wish to create. Our factory provides a variety of label templates, including RFID-specific options. We also offer a range of RFID chips tailored to meet your specific requirements.

High Customization

Custom tags are designed from the ground up to meet the needs of specific applications, with unique variables for nearly every option listed below. A semi-custom tag typically starts as a standard tag but offers additional customization options, such as custom printing, encoding, or specific backings and attachment methods.

Sample Confirmation

Before proceeding with full-scale production, we offer a sample confirmation process to ensure that the RFID tags meet your exact specifications and application requirements.

Mass Production

Our mass production process for RFID tags is designed to deliver high-quality, reliable products at scale, ensuring that your business has a steady and consistent supply of RFID solutions tailored to your needs. Leveraging state-of-the-art manufacturing facilities and advanced technology, we maintain efficiency and precision throughout the production cycle.

Related Products

Customize any types RFID tags from our factory to meet your own requirements.