- Home

- Custom RFID Tags

- Washable High Temperature UHF RFID Tags Hotel Laundry Tags

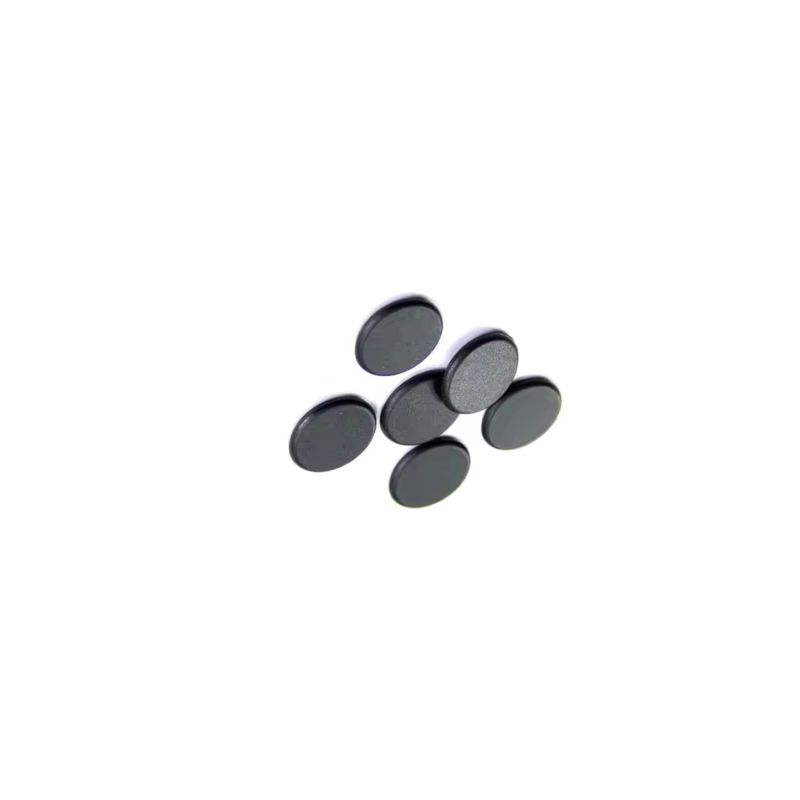

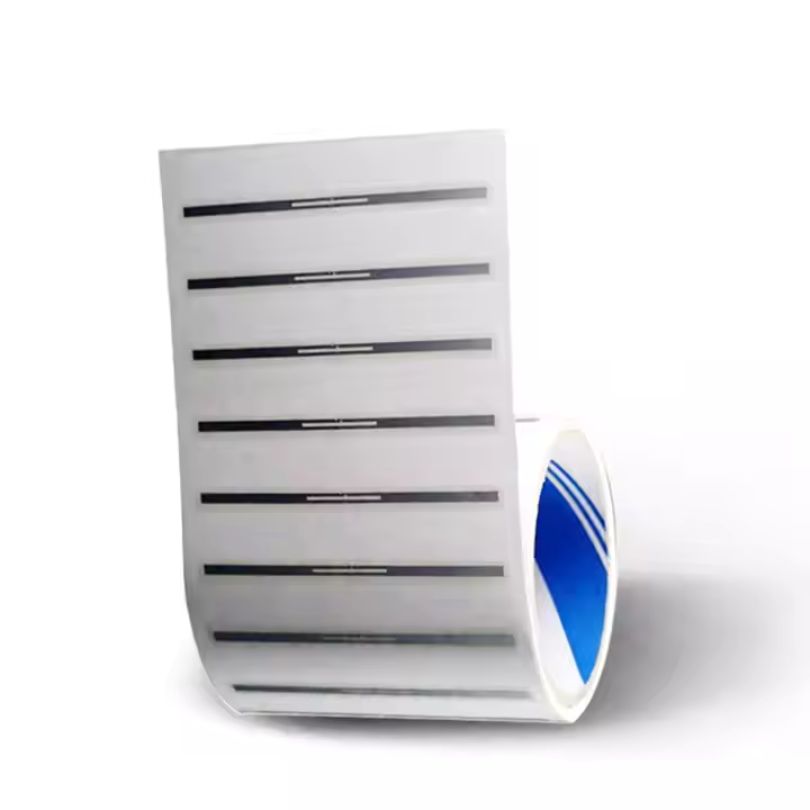

Washable High Temperature UHF RFID Tags Hotel Laundry Tags

Durable High Temperature UHF RFID Tags for Industrial Laundry Management

Industrial laundries, hotels, hospitals, and uniform rental services face daily challenges with manual sorting, item loss, and inefficient inventory tracking. Our durable, washable High-Temperature UHF RFID Tags are purpose-built to withstand harsh laundering environments, including high-temperature washing, drying, chemical exposure, and mechanical stress.

Engineered with advanced UHF RFID technology (860–960 MHz), these tags enable automated, accurate, and bulk tracking of textiles, ensuring real-time visibility and significant cost savings across your operations.

Why Choose High Temperature UHF RFID Tags for Laundry Management?

Traditional textile tracking is slow, labor-intensive, and error-prone. Implementing UHF RFID laundry tags transforms the workflow:

- Resistant to High Temperatures – Survives repeated exposure to washing (up to 95°C), drying, and ironing/pressing (up to 220°C)

- Faster, Automated Processing – Identify hundreds of items in seconds without manual scanning or line-of-sight

- Loss Prevention & Asset Protection – Minimize garment loss, theft, and replacement costs

- Lifecycle Tracking – Monitor item usage and plan replacements based on real-world data (wash cycles counted)

- Real-Time Inventory Visibility – Know exactly where your assets are across facilities

With bulk scanning capability and integration into laundry management software, these tags dramatically enhance operational efficiency and accountability.

Features & Benefits of Our High Temperature UHF RFID Tags

Engineered specifically for commercial laundry conditions:

- Exceptional Durability – Proven to survive 200+ industrial wash cycles

- High Temperature Tolerance – Washable at 95°C, dryable at up to 200°C, ironable at up to 220°C

- Chemical & Mechanical Resistance – Withstands detergents, alkalis, bleach, abrasion, squeezing, and high-pressure extraction

- Reliable UHF Read Performance – Up to 7 meters read range, even after extensive use

- IP68 Waterproof Rating – Secure encapsulation for full immersion and pressure resistance (up to 60 bar)

- Flexible Integration – Sew-in or heat-seal options available to fit a wide range of textile products

- Passive, Maintenance-Free Operation – No batteries required; the reader’s signal powers tags

Where to Use Washable High Temperature UHF RFID Tags

- Hotels & Resorts – Bed linens, towels, robes, uniforms

- Hospitals & Clinics – Scrubs, patient gowns, bedsheets, surgical drapes

- Industrial Laundries – Bulk garment processing and client asset tracking

- Uniform Rental Services – Track employee uniforms and workwear lifecycles

- Entertainment & Theme Parks – Manage costumes and performance outfits

Seamlessly integrate into existing laundry processes using standard UHF RFID readers and EPC Gen2-compatible software systems.

Technical Specifications Overview

| Feature | Specification |

| Frequency | UHF 860–960 MHz (Global) |

| Protocol | EPC Class 1 Gen 2 / ISO 18000-6C |

| Chip Options | Impinj Monza R6-P, NXP UCODE 8/9 (Specify on order) |

| Material Options | Flexible Textile Substrate, PPS, Nylon, Silicone |

| Dimensions | Standard: 55×12mm, 70×15mm; Custom sizes available |

| Mounting Method | Sew-in, Heat-seal pouch |

| Max Washing Temp. | Up to 95°C (203°F) |

| Max Drying Temp. | Up to 180–200°C (356–392°F) |

| Max Ironing/Press Temp. | Up to 220°C (428°F) |

| Chemical Resistance | Excellent (Detergents, Alkalis, Bleach) |

| Water Pressure Resistance | Up to 60 bar |

| Typical Read Range | 3–7 meters (environment dependent) |

| Wash Cycles | >200 cycles guaranteed |

| IP Rating | IP68 |

| Customization Options | Pre-encoding, laser engraving, custom logo printing |

Automate, Protect, and Optimize Your Laundry Operations Today

Upgrade your textile laundry system with our durable, washable High Temperature UHF RFID Tags — trusted by laundries, hospitals, and hospitality groups worldwide.

- Industry-Proven Durability

- Seamless Software Integration

- Competitive Wholesale Pricing Available

FAQ

What makes a UHF RFID tag suitable for high-temperature laundry applications?

High-temperature laundry RFID tags must withstand washing, drying, ironing, and chemical exposure without degradation — all while maintaining consistent RFID performance.

How are laundry RFID tags attached to textiles?

Tags can be sewn into seams or hems or heat-sealed into protective fabric pouches to ensure durability throughout laundry cycles.

Will the tags survive commercial laundry environments?

Yes. Our tags are built to survive over 200 industrial laundry cycles, including high-pressure extraction, high-heat drying, and chemical exposure.

Can these RFID tags track the number of wash cycles for each item?

Yes. Integration with laundry management software allows you to track wash cycles, helping schedule preventive maintenance or garment replacement.

Are these laundry RFID tags customizable?

Absolutely. We offer custom printing, pre-encoding, and sizing options to fit your branding and operational needs.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.