- Home

- Custom RFID Tags

- Long Reading Distance Soft Flexible RFID Metal Label

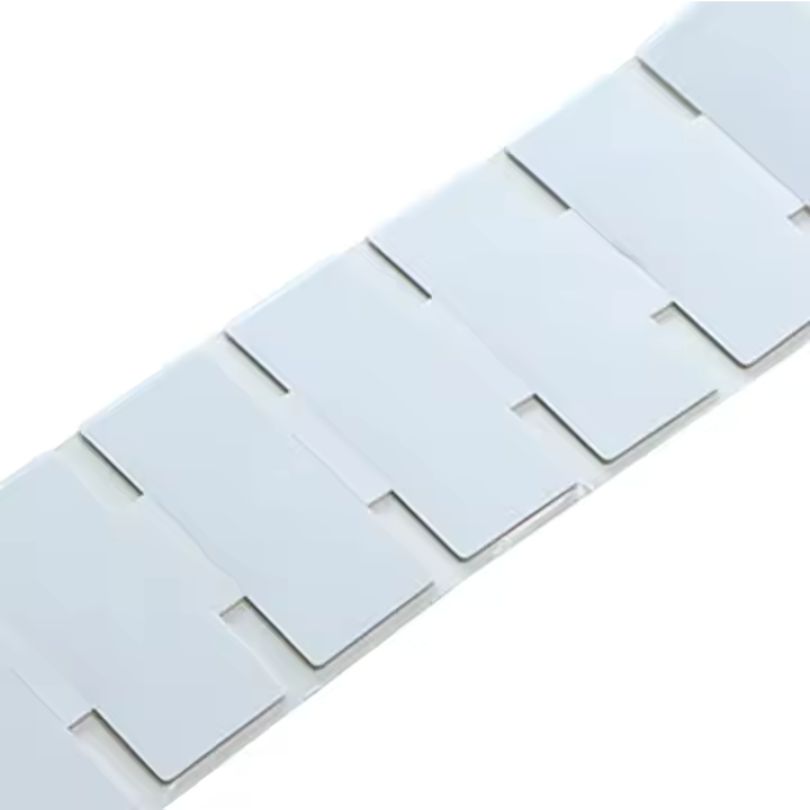

Long Reading Distance Soft Flexible RFID Metal Label

Revolutionizing Asset Tracking with Long-Range Flexible Technology

In the ever-evolving world of asset tracking and inventory management, the RFID Metal Label emerges as a cutting-edge solution designed to meet the demands of modern industries. This long reading distance, soft, and flexible label is specifically engineered to perform exceptionally well on metal surfaces, overcoming the limitations of traditional RFID tags.

Adopting the RFID Metal Label revolutionizes the way organizations track and manage assets. Its long reading distance and reliability on metal surfaces address common challenges faced with traditional RFID solutions. By investing in this technology, businesses can achieve greater operational efficiency, accuracy, and return on investment.

Superior Flexibility and Long-Range Performance

The RFID Metal Label is crafted from soft, flexible materials, allowing it to conform seamlessly to curved and irregular metal surfaces. Its advanced antenna technology and specialized anti-metal layer enable reading distances of up to 9 meters on metal surfaces, enhancing efficiency in asset tracking by allowing rapid scanning of multiple items without direct line-of-sight.

Durable and Adaptable for Harsh Environments

Designed to withstand challenging conditions, the RFID Metal Label boasts robust durability. It is resistant to water, dust, chemicals, and UV exposure, making it suitable for indoor and outdoor applications.

The high-performance permanent adhesive ensures it remains securely affixed to metal surfaces, even in extreme temperatures and rugged industrial environments.

Technical Specifications

Understanding the technical aspects of the RFID Metal Label is essential for assessing its suitability for your applications. Below is a detailed technical data table:

| Parameter | Specification |

|---|---|

| Label Type | Soft, Flexible RFID Metal Label |

| Operating Frequency | UHF 860-960 MHz |

| RFID Chip | EPC Class 1 Gen 2 |

| Reading Distance | Up to 6 meters (19.7 feet) on metal surfaces |

| Material | Flexible PET with specialized anti-metal layer |

| Dimensions | Customizable; typical size 60mm x 25mm |

| Adhesive | High-performance permanent adhesive suitable for metal surfaces |

| Temperature Range | -25°C to +85°C (-13°F to +185°F) |

| Durability | Resistant to water, dust, chemicals, and UV exposure |

| Compliance Standards | ISO/IEC 18000-6C |

| Print Compatibility | Compatible with thermal transfer printers for on-site printing |

| Application Surface | Optimized for metal surfaces |

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

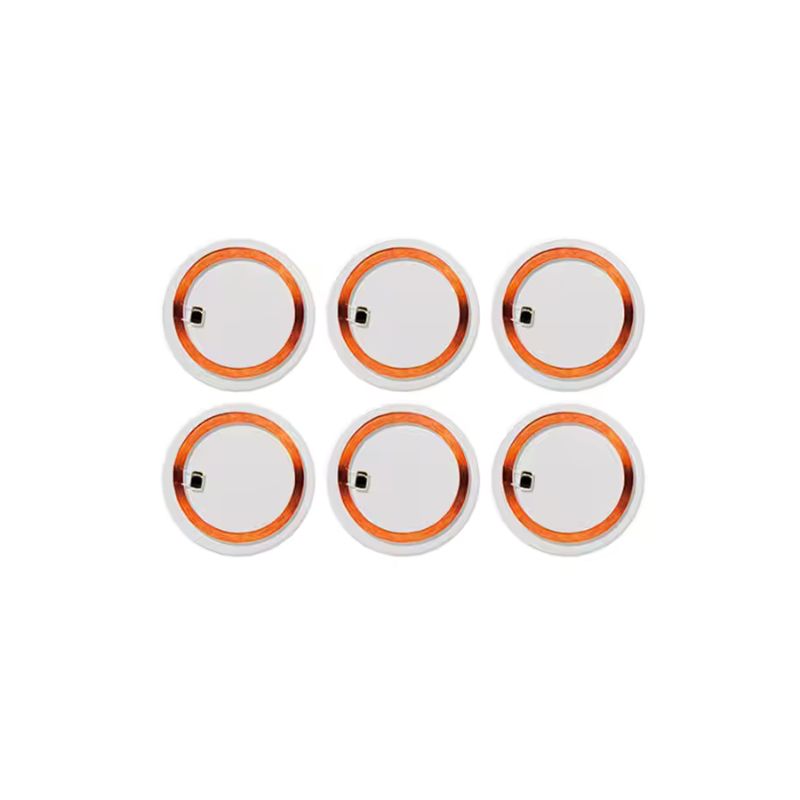

Related Products

Customize any RFID tags from our factory to meet your requirements.