HF and UHF RFID: A Comprehensive Guide to Frequency in Modern RFID Systems

Are you wondering what is the difference between UHF RFID and HF RFID? As someone specializing in explaining the difference between UHF RFID and HF RFID, I’ve worked on countless projects where selecting the right frequency could make or break an RFID system deployment. In today’s world, there are several types of RFID—from low frequency to high frequency and ultra-high frequency—each suited for various needs.

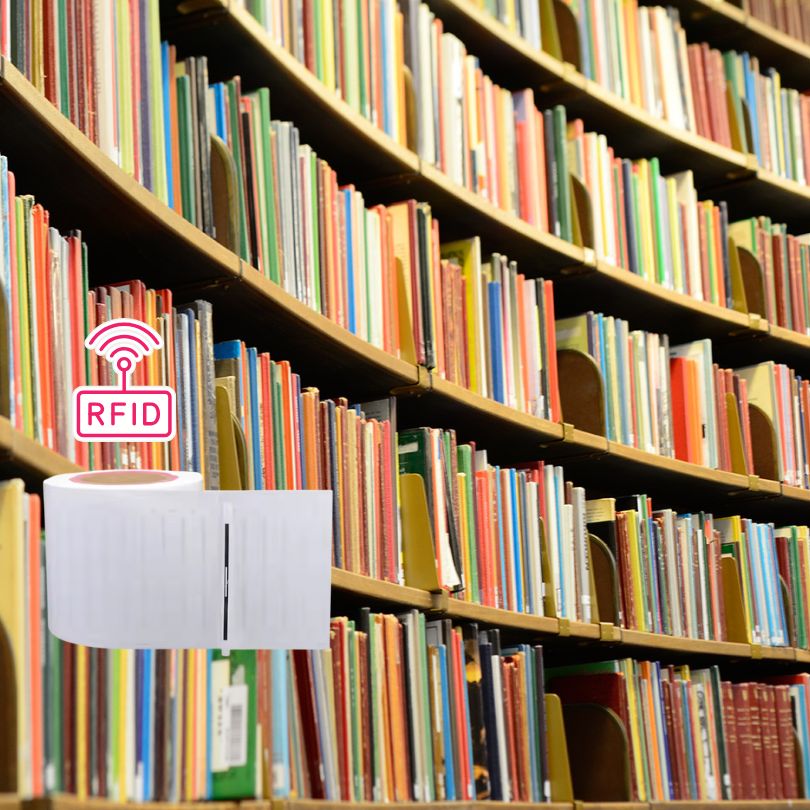

Whether in Retail, Logistics and Supply Chain, Transportation and Parking Management, Manufacturing, Healthcare, Asset Management and Security, Agriculture and Livestock Management, Education and Library Management, or Apparel and Textiles, choosing the correct RFID system is crucial. Ordering from me ensures you receive expert advice, custom HF RFID or UHF RFID solutions, and unparalleled support. Let’s explore how these frequency options can transform your operations and why you should seek a personalized consultation.

HF and UHF: The Differences Between RFID Frequencies

One of the most common questions is, “What’s the difference between UHF and HF?” This goes right to the heart of the differences between RFID technologies. Radiofrequency identification comes in many frequencies and types of RFID, but the two most popular are HF (high frequency) and UHF (ultra-high frequency). Let’s explain how these radio waves behave differently and why that matters.

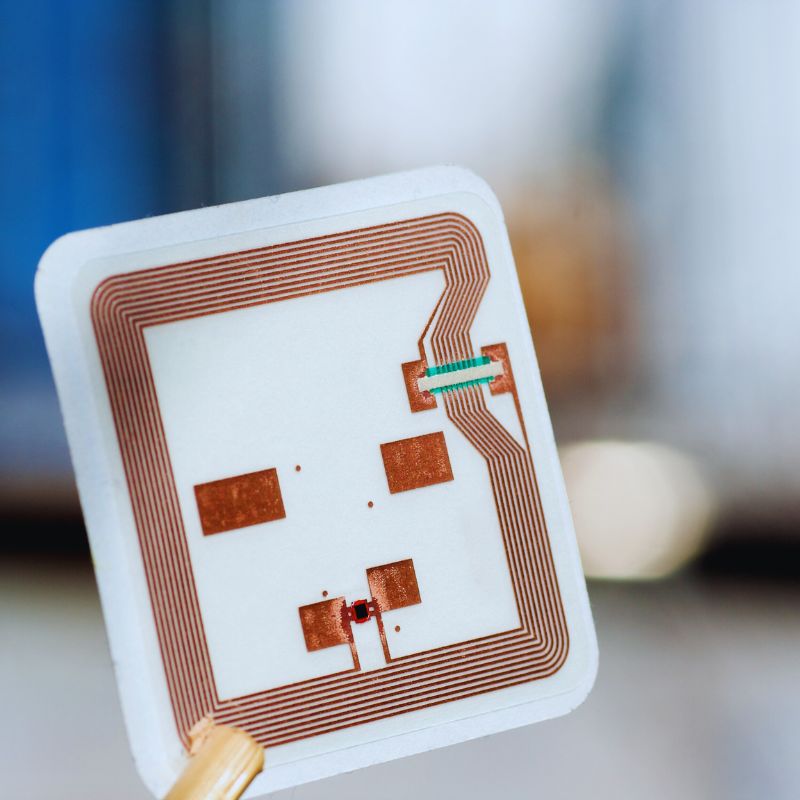

HF (13.56 MHz) sits in the high-frequency RFID range. InHF systems, the RFID tag, and RFID reader, communicate over a moderate read range—usually just a few inches to a couple of feet, depending on the tags’ design and power. HF RFID technology is especially suitable when a short read range is acceptable or preferred, such as in payment cards, library management, or event ticketing. These tags are standardized thanks to several HF standards (like ISO 14443 and ISO 15693).

In contrast, UHF RFID generally covers 300 MHz to 3 GHz; more specifically, UHF operates between 860 to 960 MHz, known as the ultra-high frequency band. This frequency band offers a longer read range—often up to several meters—and faster data transfer rates than LF or HF. That’s why most new RFID projects are leaning toward using UHF. However, the choice of frequency must align with the environment, such as the presence of metal, liquids, or other factors associated with using each frequency band.

Quote from a Client:

“We invested in UHF RFID and saw an immediate improvement in our inventory tracking. The read range improved drastically, and data transfer was seamless.”

How to Choose the Right RFID System for Your Needs

Evaluating Active RFID Systems, HF vs. UHF

When choosing an RFID tag, you should consider whether you need active RFID and passive RFID or purely active RFID systems for your project. Active RFID systems use a battery-powered tag that continuously transmits, while passive UHF RFID tags rely on power from the reader. Each approach has its own RFID applications:

- Active RFID systems: Best for long-distance tracking (e.g., vehicle identification in parking lots).

- Passive UHF: Great for item-level tagging, cost-effective RFID tags, and broad usage.

- HF RFID: Ideal for contactless payment, library books, ID badges, and environments requiring a short read range.

Because radio waves in HF differ from those in UHF systems, there is significant variance in frequency coverage, RFID transmission modes, and data transfer capabilities. For instance, HF (around 13.56 MHz) can pass through liquids with fewer issues than ultra-high frequency, making it perfect for certain RFID solutions tailored to Healthcare or Asset Management in fluid-heavy environments.

Key Frequency Band Considerations

Remember, frequency refers to the size of the radio wave, and UHF frequencies typically mean higher frequencies in the range from 300 MHz to about 3 GHz. Meanwhile, many parts of the world operate in low frequency, commonly called LF RFID or HF. A low-frequency RFID system—ranging between 125 and 134 kHz—provides a short read range but can be very robust in environments with interference from metals or liquids. Meanwhile, HF frequencies are more universal for mid-range scans, and UHF RFID technology can stretch to a more extended read range.

- LF RFID systems: 125-134 kHz, typically used for animal tagging or industrial settings requiring low-frequency RFID.

- HF systems: 13.56 MHz, widely deployed for public transportation cards, access control, etc.

- UHF RFID systems: Operate from 860 to 960 MHz, aligning with the UHF gen2 standard or UHF standard protocols.

These represent different types of RFID systems in terms of operating frequency bands. Each frequency band provides a short or long read distance depending on design, environment, and the presence of interfering materials.

Overcoming Challenges: HF and UHF in Real-World Applications

Handling Environmental and Industry-Specific Issues

In real-world deployments, it’s vital to know how these systems operate. Metals, liquids, or extreme temperatures can influence HF and UHF RFID. Radio waves behave differently across low-frequency, HF, and ultra-high frequency. For instance, certain industries (like Healthcare) might prefer HF because it’s less sensitive to fluids. At the same time, large-scale warehouses might leverage UHF tags, or UHF tags are easier solutions for scanning multiple items at once.

Also, rain RFID—“RAdio frequency IdentificatioN”—is the brand name for passive ultra-high frequency RFID, often used in item-level tagging across Retail and Logistics. Rain RFID systems comply with GS1 UHF Gen2 protocols, ensuring global interoperability. Rain RFID is used for everything from tracking store apparel to monitoring supply chain movements. Indeed, this technology is now the fastest-growing segment of the RFID market.

Practical Usage Instructions and Tech Specs

Below is a quick table comparing core HF and UHF specifications:

| Specification | HF (13.56 MHz) | UHF (860 to 960 MHz) |

|---|

| Read Range | Up to ~1 meter (often less) | 1-10 meters, sometimes more |

| Data Transfer | Moderate | Faster |

| Environmental Sensitivity | Less affected by liquids, short distances | More affected by liquids/metal, better for large-scale scanning |

| Usage Examples | Library books, payment cards, secure access | Retail item tagging, warehouse tracking |

When deploying these tags in environments like Agriculture or Manufacturing, it’s essential to run tests to see which tag frequency suits your needs. Many new RFID projects use UHF simply because the read range is better for items in motion, but specialized markets may still favor HF or LF RFID.

Environmental Impact and Customer Feedback

I’ve deployed HF vs UHF solutions in sensitive habitats—like greenhouses—where low-frequency RFID or HF technologies performed best due to humidity and metallic racks. Meanwhile, large-scale distribution centers rave about the efficiency gains from UHF systems. Here’s what some clients had to say:

Customer Review (Manufacturing Sector):

“Our move to active RFID systems with UHF RFID drastically improved our inventory flow. The scanning speed and RFID reading success rate soared.”

Customer Review (Healthcare Industry):

“Thanks to HF RFID technology, we can track medical tools reliably. The short read range is perfect for quick point-of-use scanning with minimal error.”

Why Partner With Me?

You tap into deep expertise across multiple industries by trusting me with your RFID solution. I understand the RFID market segment where your project lies and can tailor an approach that meets your needs. I also have access to RFID products that comply with the UHF gen2 standard, ensuring global compatibility. Whether you want to harness HF for secure contactless transactions or UHF for large-scale logistics, I’ll guide you through selecting the right RFID devices, from LF tags to HF tags and UHF tags.

Action Step: Reach out for a consultation. I am ready to design solutions tailored to your operating environment, ensuring minimal downtime and maximum ROI.

Useful Resources and Links

Are you looking for more detailed information or specialized tags? Check out these pages for semantically relevant insights:

- High-Performance HF Tags for Access Control

- Streamlined UHF Tags for Apparel Tracking

- RFID Solutions for Healthcare & Pharmaceuticals

- Industrial-Grade LF Tags for Unique Environments

The AIDA Model: Driving You Toward the Right Choice

- Attention: You’ve learned how HF and UHF differ and how radio waves can impact your business.

- Interest: You’ve seen real-world applications in Retail, Logistics, Manufacturing, and more.

- Desire: Ready to implement or upgrade your RFID system? My proven track record in RFID projects stands out in the RFID market.

- Action: Contact me for a personalized plan to boost efficiency, security, and data accuracy.

Because rain RFID solutions remain the RFID’s fastest-growing segment, most new RFID projects leverage them. If you’re still on the fence, remember that rain RFID systems comply with global standards, making them future-proof. Whether you need the short-read range benefits of HF or the robust scanning power of UHF frequencies, I offer flexible RFID solutions tailored to your exact operational demands.

Technical Highlights to Remember

- Radio waves behave differently at low frequency, HF, and ultra-high levels.

- UHF RFID typically ranges from 300 MHz to 3 GHz and adheres to the UHF gen2 standard.

- HF RFID runs at 13.56 MHz and is a prime choice where accuracy at closer proximity is key.

- Active RFID systems can expand the range further but at higher costs.

- UHF can result in a faster scan rate than LF or HF, and tags are easier and cheaper to produce in bulk.

- The environment can impact RF, so thorough testing is essential.

If you’re ready to enjoy these benefits, my expertise ensures you’ll deploy a robust RFID system swiftly and cost-effectively. Let’s turn your vision into a reality—reach out now!