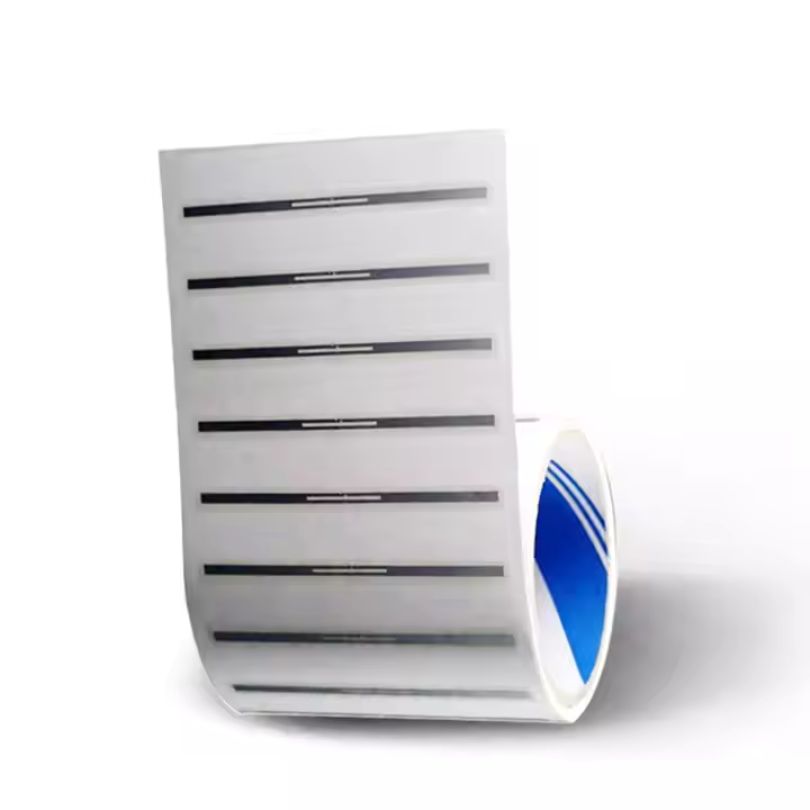

RFID Laundry High Temperature RFID Tag Small Button Tag

Durable High Temperature RFID Tag Solutions for Extreme Environments

In industries where extreme conditions are the norm, reliable asset tracking can be challenging. Our high temperature RFID tag solutions are engineered to withstand extreme temperatures while providing consistent and reliable performance. These specialized tags are designed for use in environments that require exceptional heat resistance and ensure that your asset tracking is not compromised.

The high temperature RFID tag is the perfect solution if your business needs reliable RFID tracking in high-temperature environments. From automotive to industrial manufacturing, our high-temperature tags provide consistent performance, and offer a read range of up to 7 meters on metal, ensuring accurate identification and tracking.

Unmatched Durability with High Temperature RFID Button Tag

Our high temperature RFID tag is constructed using premium-grade materials that allow them to operate effectively in extreme temperatures. Traditional RFID tags can become damaged or fail to perform in high-temperature conditions; however, our tags are designed to withstand these challenges, and are able to perform in temperatures ranging from -40°C to +200°C. These tags are designed for applications requiring high heat exposure. Our high-temperature tags can endure high-temperature processes, making them ideal for various industrial and automotive manufacturing operations.

The tag is made from robust materials that are able to withstand frequent handling, cleaning processes, and exposure to high temperatures. The tag’s rugged design ensures longevity and reliable data capture, allowing for efficient tracking applications even in the harshest of environments. Our high-temperature tags are available in multiple options including shape, size, and mounting options, providing you with a perfect solution that meets your specific requirements.

Versatile Applications of Laundry Button RFID Tag

Our high temperature RFID tag is incredibly versatile, which makes them suitable for a wide range of applications. They can be used for tracking assets in demanding high-temperature production environments, providing reliable identification and tracking. They are ideal for the automotive, aerospace, and healthcare industries, as well as in the textile industry for laundry management.

These tags are designed to mount on metal, and perform consistently even when attached to metal surfaces. The tags are specifically designed to withstand the extreme heat of the laundry process, allowing for more efficient and effective laundry operations. With their small form factor, our tags are easy to integrate into various items without adding bulk or causing interference.

This makes them perfect for various applications, from tracking small components to larger industrial equipment. The use of passive RFID technology means that our tags do not require a power source of their own, providing a long-lasting and cost-effective solution for your business. If you need RFID tags that can withstand high temperatures, you have come to the right place.

Advanced Technology and Seamless Integration of UHF RFID

Our high temperature RFID tag utilizes cutting-edge RFID technology to ensure consistent and dependable performance. The tags operate in the uhf frequency band, providing a long read range and the ability to read multiple tags simultaneously.

These tags are compliant with international standards and are compatible with most RFID readers, making it easy to integrate into your existing RFID system. This makes them ideal for tracking metal assets, as well as asset tracking in other demanding high temperature environments. We offer multiple options, including different frequency bands such as 915 mhz and 13.56 mhz RFID. Whether you are deploying a new RFID system or integrating the tags into an existing system, our tags provide seamless performance.

Our high temperature tags ensure accurate and reliable data capture, providing real-time visibility of your assets in your production environments.

| Feature | Specification |

| Type | Passive UHF RFID |

| Frequency | UHF (860-960 MHz), 915 Mhz, 13.56 mhz |

| Operating Temperature | -40°C to +200°C |

| Read Range | Up to 7 meters (on metal) |

| Mounting Options | Screw, Rivet, Adhesive |

| Material | Nylon, FR4 |

| IP Rating | IP67 – IP68 |

| Data Capacity | Up to 2000 bits |

If you are seeking a reliable, durable, and high-performing solution for asset tracking in high-temperature conditions, look no further. Contact us today to discuss your specific requirements and learn how our high temperature RFID tag can enhance your operations. We offer a selection of free samples and are able to offer you a very competitive price on our high-quality tags.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.