- Home

- Custom RFID Tags

- UHF Asset Tracking RFID Printable Anti Metal Tag

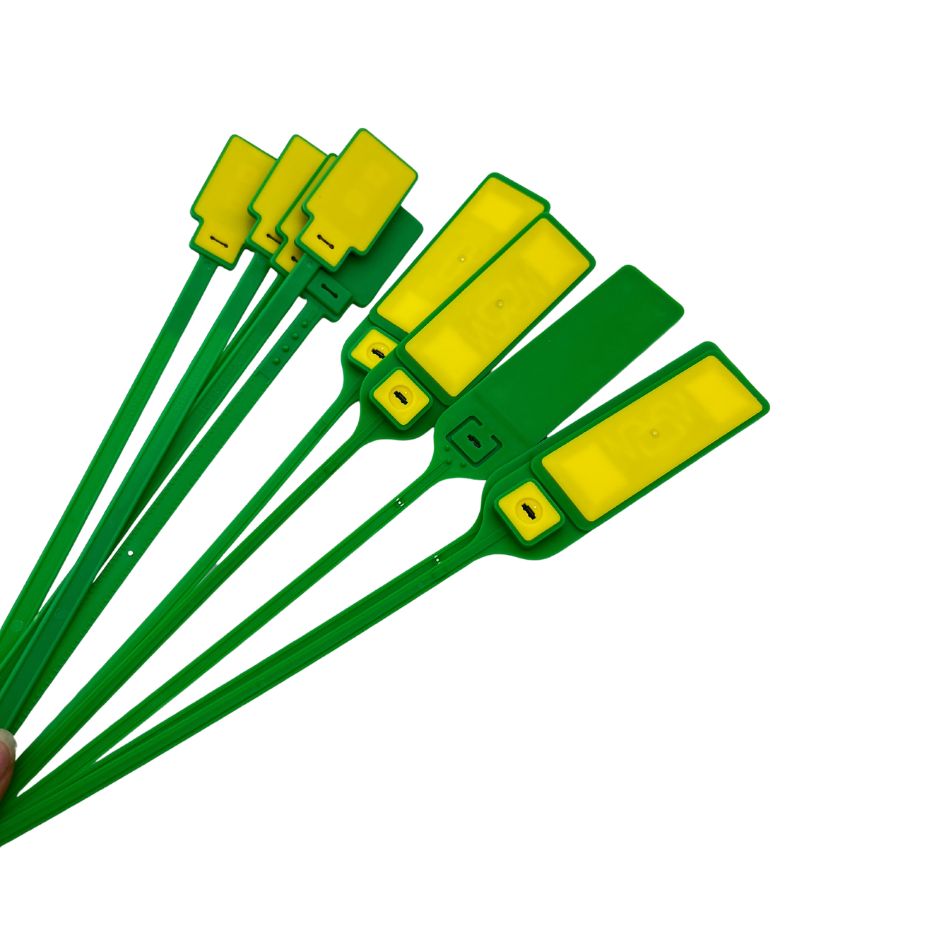

UHF Asset Tracking RFID Printable Anti Metal Tag

Asset Tracking RFID Tags – Printable UHF Anti-Metal RFID for Industrial Use

Our Asset Tracking RFID solution is a UHF-based, printable RFID label designed for durable and high-accuracy asset monitoring. Unlike standard tags, this model is engineered with anti-metal shielding, making it the perfect Anti Metal RFID Tag for applications involving metallic surfaces, containers, tools, and industrial assets.

With printable face stock, customizable EPC memory, and strong adhesive, this tag delivers exceptional performance in demanding supply chain, manufacturing, and IT asset tracking environments.

If you’re looking for an RFID for asset tracking solution that’s durable, customizable, and easy to deploy, this tag checks all boxes.

Key Features of Our Asset Tracking RFID Tags

- Metal-Safe Performance

Every Asset Tracking RFID tag is engineered to work flawlessly on metallic surfaces using Anti Metal RFID Tag technology. - Long-Range Readability

Optimized antenna designs enable extended read ranges without line-of-sight requirements. - Durability in Harsh Environments

Resistant to heat, water, dust, and impact—perfect for industrial, logistics, and outdoor use. - Customizable Printing & Encoding

We offer logo printing, barcoding, serial numbering, and data encoding on any Asset Tracking RFID label or hard tag. - Active & Passive Options

Choose passive tags for budget-friendly static tracking or active tags for real-time dynamic visibility. - Plug-and-Play Integration

Fully compatible with existing inventory and asset-tracking software systems.

Real-World Use Case

Industry: Utility Equipment Management

A leading energy provider implemented over 10,000 Asset Tracking RFID tags across toolboxes, power generators, and trailers. These Anti Metal RFID Tag units provided:

Real-time equipment location updates

75% reduction in manual audits

Lower losses and improved tool availability

The system integrated directly with their existing ERP and eliminated human errors in inventory reporting.

Technical Specifications

| Feature | Description |

| Frequency Options | UHF (860–960 MHz), HF (13.56 MHz), optional NFC support |

| Tag Type | Printable labels, hard tags, mini RFID tags |

| Surface Compatibility | Designed as Anti Metal RFID Tags for direct attachment to metal |

| Operating Temp | -40°C to +85°C (custom high-temp tags available) |

| Read Range | Passive: up to 10m |

| Durability | Waterproof, UV-resistant, anti-impact |

| Customization | Shape, encoding, printing, barcode, color options |

| Standards Compliance | ISO 18000-6C, EPC Gen2, RoHS |

Applications of Asset Tracking RFID Tags

Our Asset Tracking RFID solutions are used in:

- Tool & Equipment Tracking

- Industrial Asset Monitoring

- Field Service & Utility Fleet Management

- Hospital Equipment & Medical Device Inventory

- Logistics & Warehouse Management

- Retail Shelf & Inventory Tracking

- Construction Materials Tracking

If you need RFID for asset tracking, we have a scalable solution for you.

Why Choose Our Anti Metal RFID Tag Solutions?

- Metal-Safe Design: Unlike standard tags, our Anti Metal RFID Tags function reliably on all metallic surfaces

- Custom Printed Tags: Add your logo, barcode, or color code for brand and operational alignment

- Expert Support: Get personalized recommendations for your environment and use case

- Flexible Deployment: Easily integrate with your existing systems or ERP platforms

- Best Price Guarantee: Competitive factory-direct pricing on all bulk orders

- Fast Lead Times: Rapid production and international shipping options

Ready to enhance your efficiency with the most advanced Asset Tracking RFID tags?

📩 Contact us today to get a free quote or request samples of our high-performance Anti Metal RFID Tag products.

Upgrade your tracking, reduce losses, and gain real-time visibility across your assets.

FAQ

Can your RFID tags be used directly on metal surfaces?

Yes. These are specialized Anti Metal RFID Tags, engineered to eliminate interference from metallic surfaces.

What’s the difference between passive and active Asset Tracking RFID tags?

Passive tags are ideal for simple location tracking with lower cost. Active tags provide long-range, real-time updates and are battery-powered.

Can I integrate your tags with my current inventory system?

Absolutely. Our RFID for Asset Tracking solutions work with most ERP, WMS, and asset software platforms.

Do you offer custom encoding or printing?

Yes. You can add serial numbers, barcodes, QR codes, and logos to any Asset Tracking RFID product.

What’s the minimum order quantity?

MOQ typically starts from 100 pieces, depending on the customization. Contact us for details or bulk pricing.

Get Your Custom RFID Tags

As a leading custom RFID tag manufacturer, we craft solutions based on the unique needs of your operation. We offer a wide range of customization options, including material, size, frequency, encoding, and read distance, ensuring each RFID Tag is perfectly customized to your requirements. No matter what application you use RFID tags for, we can provide rugged, reliable RFID tags that meet the highest quality and durability standards. Here are the main ways we customize RFID tags to fit your needs.

Material Selection

Material is key for customizing RFID tags. Plastic works in harsh conditions, while softer materials suit delicate spaces. Different materials also affect signal performance. Pick what fits your use case to ensure your tags last and work reliably.

Customized Size

Size shapes usability. Small tags fit tight spaces or tiny items, while larger tags are easily read. In crowded areas, sleek tags prevent clashes. Align shape and dimension with your goods for visibility, convenience, and performance.

Frequency Requirements

Choose LF, HF, or UHF based on read range, speed, and interference. LF and HF resist metals and liquids but have shorter ranges. UHF offers an extended range yet may face signal blocks. Match frequency to your environment for reliable performance.

Reading Distance

Define the distance at which you have to read the tag. Short distances work for retail checkouts, while warehouses may need meters of coverage. Antenna design, reader settings, and power outputs affect range.Adjust these factors to capture data accurately at the distance you need.

Encode

Plan how data is stored on each tag. Some only hold an ID, while others contain detailed info. Decide if you need a simple EPC or added user memory. Ensure your chosen format works with existing software. Proper encoding streamlines processes and slashes errors.

Application Environment

Consider real-world conditions. Temperature swings, humidity, and chemicals can degrade tags. For outdoor use, opt for UV-resistant casings. In healthcare or food settings, ensure compliance with safety rules. Matching your tags to the environment maximizes their lifespan.

Related Products

Customize any RFID tags from our factory to meet your requirements.